Fine decoration complaints rate is high, but forced construction enterprise quality, process, cost more refined management!

Bulk hardcover repair projects usually have higher overall project coordination requirements, one is because of the hardcover repair project construction units, there are a variety of cross-operation processes, the process of scheduling, schedule requirements are high, the need for detailed pre-planning.

Second, and because each floor implementation process is different, building materials are different, if not strictly on-site control, it is easy to appear the overall collapse of the project, quality problems frequently.

After so many hardcover projects, we have learned a lot of experience and lessons, so this issue shares the “main control points of fine decoration projects” mainly related to the control process, cost, quality, and other content, divided into 7 points to expand:

A project model and site construction does not match, the owner complained about the rights of the rights

After experiencing so many hardcover projects, we have learned a lot of experience and lessons, so this issue shares the “main control points of fine decoration project” mainly related to the control process, cost, quality, and other content, divided into 7 points to expand:

1, hardcover repair project nature introduction and process description

2, fine decoration pre-entry notes

3, hardcover repair project control analysis

4, fine decoration cost management analysis

5, fine decoration to avoid the key analysis

6, transfer notes and transfer products, etc

7, post-service instructions

01

Fine decoration process index

To do a good job of finishing, not only to control costs, rush the duration but also to ensure quality, for the project team is a great test, wherein the process index is the key to the entire project management logic.

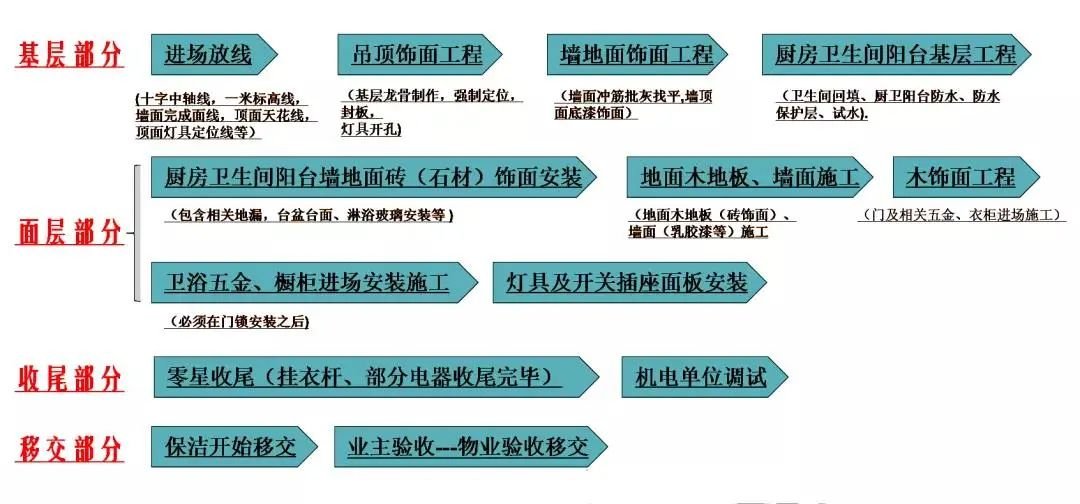

Fine Renovation Process Index: Grassroots – Surface – End – Hand over

1.1

Operation scheduling

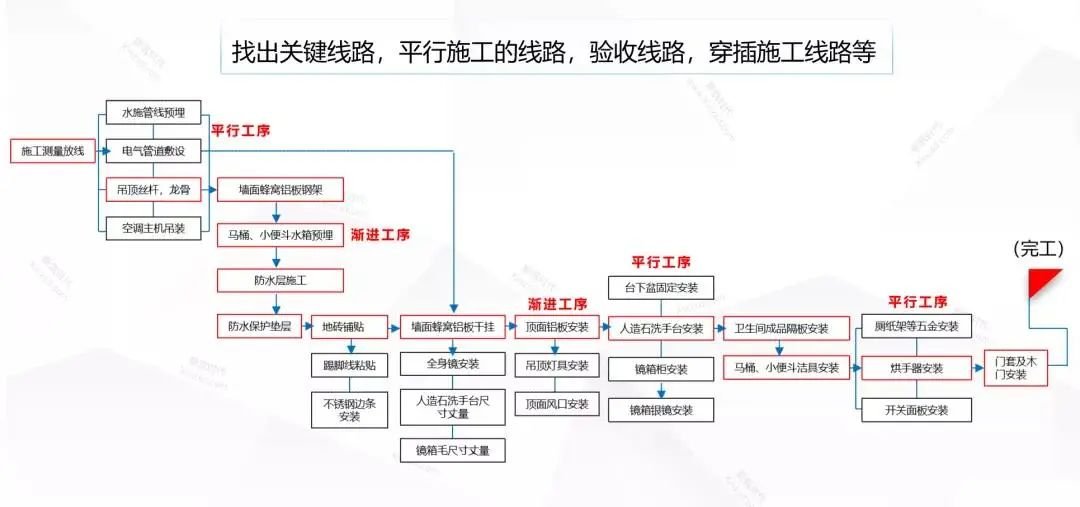

A line from the measurement – the foundation of the wall decorative surface

Process arrangement: wall cylinder covert acceptance before

1.2

Schedule

02

Fine decoration pre-entry precautions

Fine decoration works, pre-planning to be detailed, the site of the survey to be comprehensive, the pre-work to do a bit, that work has been completed half, the pre-entry considerations I classified as the following points:

2.1

Site project surrounding environment, site peripheral environment, and construction environment inspection

The environment around the project

a, before entering the project, we need to examine the project’s geographical location (busy areas, suburban areas, surrounding facilities, etc.), affecting the transportation of materials, personnel accommodation, etc.

The perimeter of the site

b, need to consider the road conditions around the project, outdoor elevator operation, ground road closure time node; Affects the way materials enter the field, vertical transportation of materials and stacking position;

On-site construction environment

c, the site construction area windows have not been closed, underfloor heating and air-conditioning equipment completed, civil site inspection. Need to consider the team material transportation mode, etc., with our construction of the regional surface division.

2.2

Notes on-site handover

The handover and acceptance of the original civil structure, quality and façade decoration, installation, etc.

(1), there is a certain deviation civil walls, we have to test the deviation of each wall, propose solutions, to achieve the unity of size, for the completion of the sub-house acceptance to do preparation.

a,size. b,verticality. c,flatness. d,elevation (smallpox, ground).

(2), civil wall painting layer of the empty drum we have to carry out careful inspection, to ensure that qualified and then hand over, so as not to rework when we surface construction, affecting the duration.

a squareness. b, paint thickness. c, empty drum

2.3

Pre-targeted special planning

Need to be more early on the project inspection and the accumulation of construction experience over the years, the combination of the two, the preparation of special construction planning, and team and owners to carry out comprehensive discussions!

Conducting in-session meetings with the team; Allocate on-site labor and schedule preparation

03

Hardcover repair project control analysis

Fine decoration for the bulk decoration way, its project management methods also need to be targeted; The specifics are divided into the following points:

3.1 Material entry organization

3.2 Model room advance room ideas

3.3 Check the implementation of the first inspection system

3.4 Bridge management with the cooperating unit

3.5 Key points of the preemption process control

3.6 Control of quality, schedule, and workforce arrangements

3.1

Material entry organization

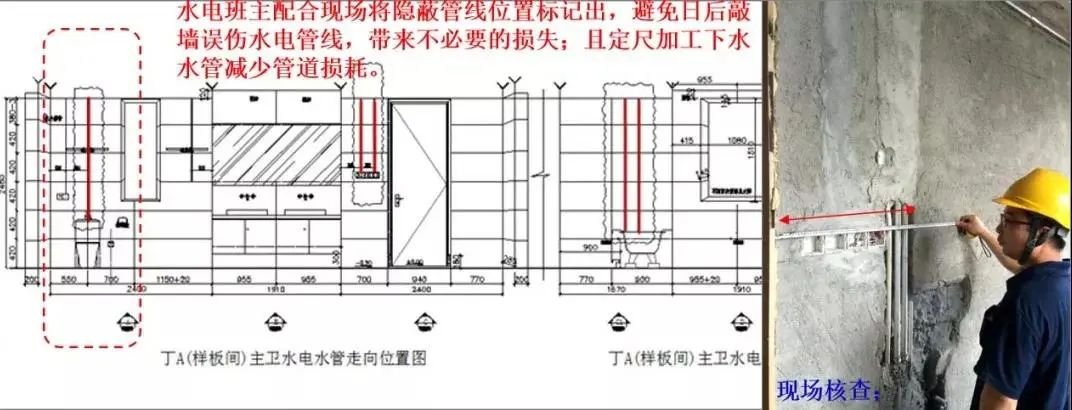

a, floor distribution of materials, accounting for the quantity before the material enters the market (project department).

b, vertical transportation of large materials, before the demolition of construction elevators, large materials are all transported upstairs.

c, material entry needs to clean up the inventory promptly.

d, A supply material statistical reporting, acceptance of quantity and quality at the time of receipt, to avoid disputes later.

e, material to the scene test assembly, due to large volume easy to early detection of problems and suppliers to communicate. Such as stone (composite thickness), finished furniture, wallpaper, hardware (bathroom, door), lamps, taps.

Material entry inventory

A supply material statistics reporting

3.2

Model advance room ideas

construction between the models is the project department’s understanding of the characteristics of the material, the material brand confirmation process.

b, different types of advanced housing are the project department of the entire construction process and the end control of the understanding process.

c, different teams of the advance room are for the team that did not carry out the model room construction and the process of working with the unit run-in.

d, a model of various materials and one-to-one production, the end of the construction process model.

3.3

Check the first inspection system

Workers in each process of the first construction, the project department personnel must be in place, unified standards, found problems resolved promptly, to later large-scale construction inspection. The items of the batch unified construction process must be first inspected, and the first inspection can be used for physical bottoming.

raw materials into the field, warehouse manager, construction staff to the scene inspection.

b, before the material installation, the project department, team leader participate in the construction.

c, pending the project department to confirm the construction process after the preparation of the technical bottom and for the main construction personnel to cross the bottom (site bottom).

d, technical bottom (oral, written, physical), for the physical bottom of the project;

a yin and yang angle of latex paint, grooves. b, the end of the stone. c, finished table basin cabinet, countertop, tap with installation. d, hardware installation.

3.4

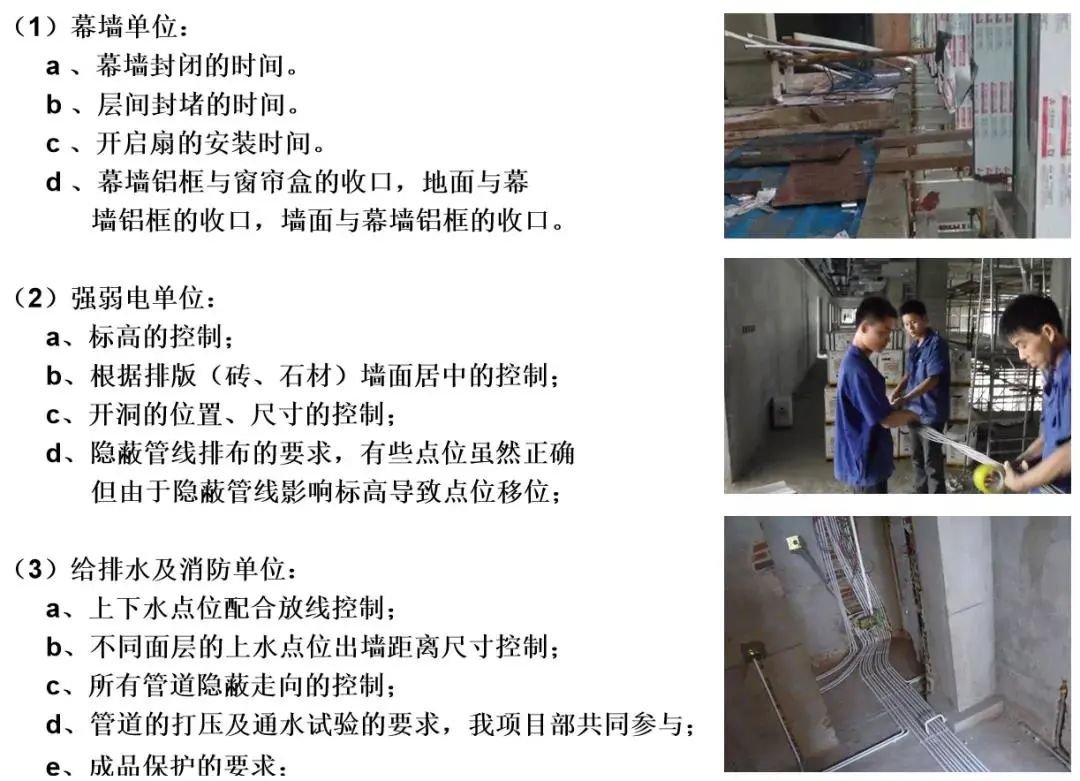

Bridge management with the cooperating unit

3.5

Key points of the preemption process control

a checkpoint control, implementation of rectification (impact of the late surface layer).

b, increase the personnel of the bottom, the bottom is a continuous process, workers are mobile, from the start to the end of the maintenance process personnel are constantly changing

c, order tracking, in the process of rushing materials is the first, can only appear materials and other people, but not people and other materials.

d, with unit control: time node, installation quality (curtain wall, floor, cabinet).

e, with the completion of the unit after the transfer to us, the transfer process requires that small parts need not be installed, pending door lock installation.

f, progress comparison analysis, through comparative analysis to find materials or labor shortage, timely communication with suppliers, teams.

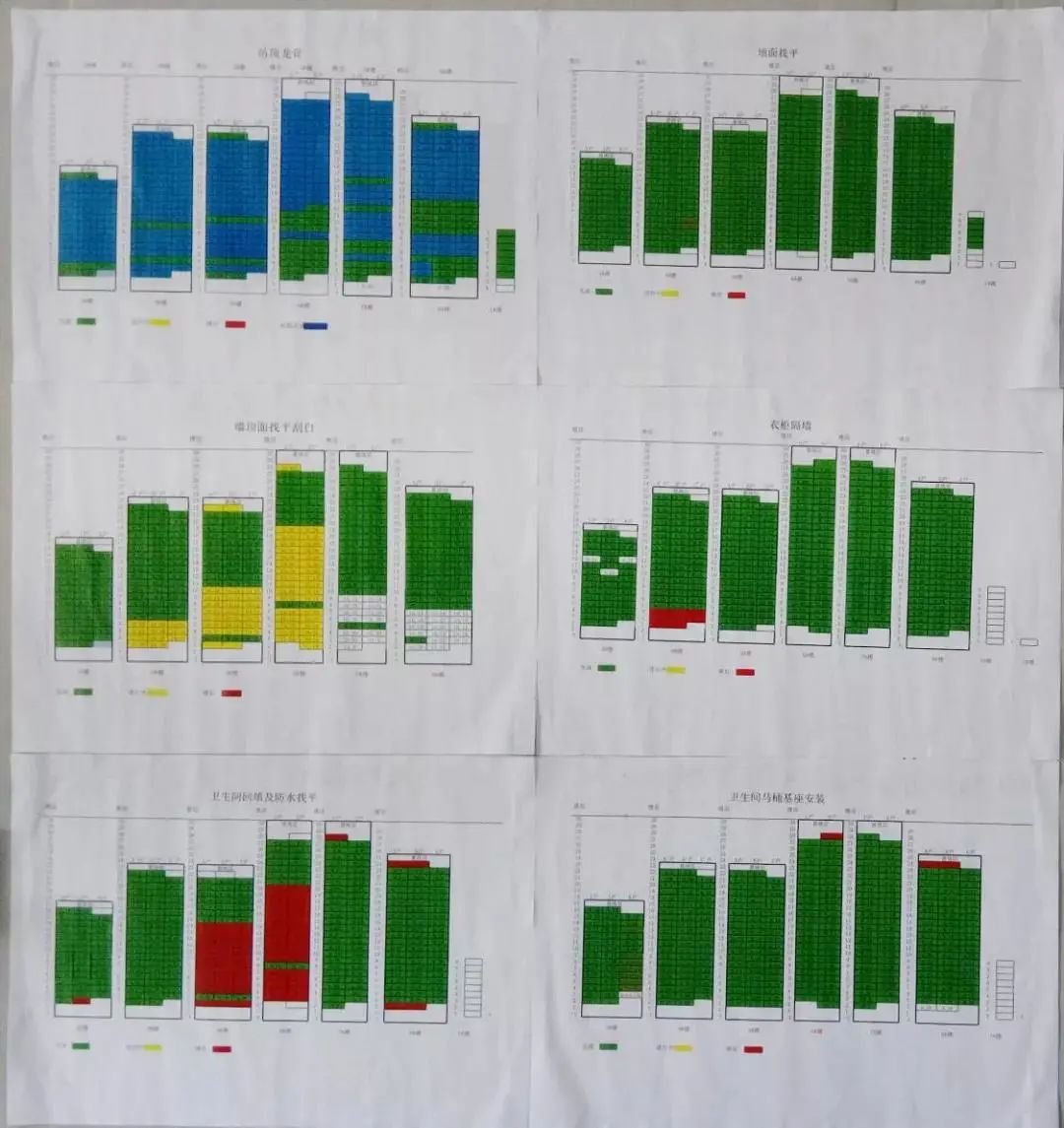

The field uses the column analysis table to count the progress of the fieldwork

Manage the management in real-time based on real-time progress

3.6

Quality control points

a fine decoration, point wide, each process to have someone to be responsible for (responsibility to point to person), every day there is record monitoring, continuous inspection, construction situation to achieve the bottom of everyone’s hearts, at a glance, to reduce the quality of common diseases.

b, material cost management: adhere to the assessment of materials, reasonable arrangement of construction processes and construction processes, strengthen the awareness of the protection of finished products.

c, technical bottom: on-site team mutual inspection and quality training

d, inspection system: due to the number of floors, rooms, everyone can not carry out a comprehensive inspection every day, project staff to develop a tour floor table, to ensure that the entire site everyday inspection does not leak layers every.

3.7

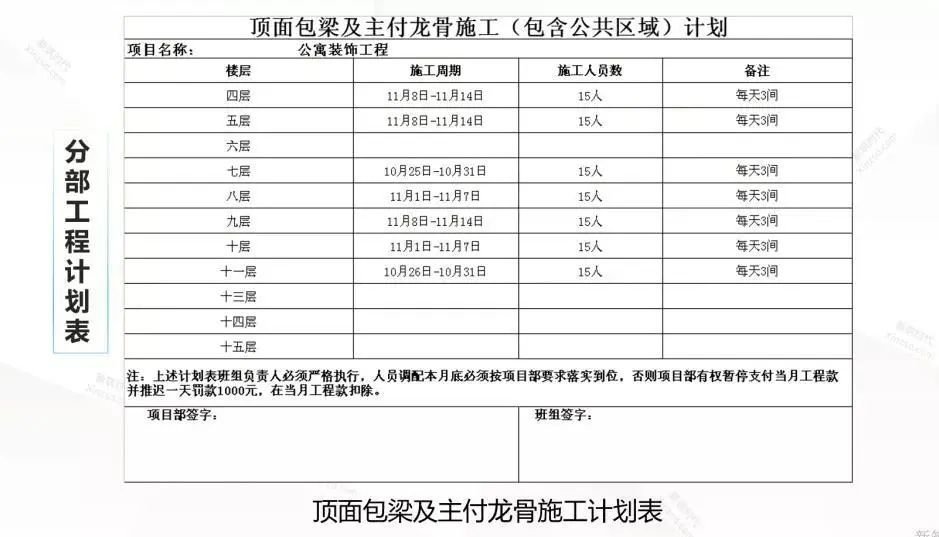

Control points for progress and workforce arrangements

a, planning to be in place, strengthen the technical and process standards of the bottom, in the process before the construction of special technical bottom;

b, the contract clear quality award and penalty rules, and timely check the cash;

c, some certain grasp is not allowed to carry out small and large-scale production, as well as stone, wood finishes of raw materials and processing capacity control.

d, the focus is on the control of people, the main is to check and rectify, to the construction site situation at good fingertips, timely detection of problems;

e, strengthen the construction concept of a piece of the collection, really achieve the requirements of productization, after the completion of a large area of product packaging conditions;

f, on-site understanding, especially in super-high-rise buildings, the workers’ commute and material transportation constraints (workers commute to work; material transportation time);

g, the entry plan of basic materials, and the order plan of the main surface materials, the project department should control the follow-up implementation.

04

Fine decoration cost control

Fine decoration for the bulk decoration, its cost-control also has a corresponding way, probably divided into the following points:

4.1 The process practice is unified bottoming and finished management

4.2 Material Early warning line volume and loss control

4.3 Control of team labor costs

4.4 Control of finished product protection

4.5 Field examples are listed

4.1

The process practice is unified bottoming and finished product control

According to the quotation and the actual situation on site, the construction process to carry out the multi-scheme comparison, to ensure quality at the same time to minimize the cost, but in the implementation process there will be deviations, mainly pay attention to the following points:

a, there is no full staff to hand over the bottom, the process or some workers did not fully following the project department to carry out the construction, need to do this kind of work of all workers and with classes together to hand over the bottom;

b, inspection is not in place, when found to have deviations can not be corrected, should be in each sub-item at the beginning of construction by a special focus inspection, to timely rectification;

c, product construction attention points

(1), the unity of the household surface layer

(2), the unified exchange of materials. Standardization and harmonization of dimensional specifications.

(3), running water work.

(4), standardized packaging protection.

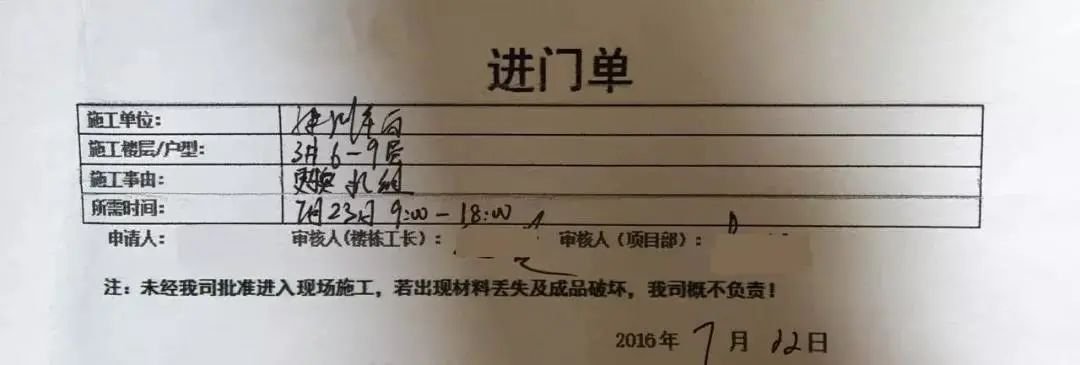

(5), floor portal management requirements.

4.2

Material-related controls

Material Determining the quantity of the warning line:

Early warning line is to be determined before the project starts, mainly related to the accuracy of statistics, need to pay attention to the following points:

a process does not understand the guide to the calculation error, this work must have construction staff, budget staff, with the class combined with the base drawings to participate in the calculation, and let the class sign confirmation.

b, the process should be by the budget staff, construction staff to the site practices to check, check, timely adjust the number of early warning lines.

Control of material loss:

a, for the characteristics of household type unified, batch operation, grass-roots materials need to be fixed-scale processing, reduce loss, but pay attention to the bottom and unified ingredients, inspection, to avoid long cut into short, short throw away phenomenon;

b, for the unified practice sub-items to take centralized stacking centralized processing, by the installation workers to lead semi-finished products to the site installation, such as door cover carpentry board grass-roots, curtain box woodworking board grass-roots, ceiling modeling, wall tiles, etc., the main attention to the site selection, team cooperation;

c, for the room more, small space characteristics, the scene needs someone to check the remaining materials concentrated summary, finished work.

d, temporary facilities control, site special woodworking board usage is often far more than the settlement volume, there is a large part of the team to do warehouse, dormitory bed board, dormitory table, including on-site utility bills, we have to strictly control this piece.

e, for the characteristics of large volume, long time, materials to be standardized, the team by a special person to use, the project department by the construction staff, budget staff to participate in the audit team picking, but the project department should pay attention to the implementation, open the green light is not good to end.

4.3

Control of team labor costs

labor costs in the early stage of the project need to be signed, which will further strengthen the team’s management and avoid the phenomenon of nest workers.

b, reasonable according to the schedule of work, help the team to control labor costs.

c, standardized practices, prevention of quality disease, reduce maintenance workload.

Construction schedule, team personnel arrangements

4.4

Control of finished product protection

a, to avoid the destruction of other units with the installation, especially the destruction of hydropower, air-conditioning units;

b, to avoid the loss of late hardware, ware, etc., to strengthen the implementation of the door opening system; Commissioner opens the door system, control too many people flow activities, in and out of the indoor construction have the corresponding out of the door (one type three);

4.5

Field examples are listed (finished).

Indoor railings for iron painting guardrails, professional manufacturers custom up to 125 yuan / M, I Division of our purchase of galvanized moment tube, welding processing, labor and materials for 45 yuan / M, the whole sent to professional manufacturers spray paint, the price of 25 yuan/M, for a total of $70/M, directly reducing costs by $55/M. Direct cost savings of more than 22300 yuan.

Stainless steel elevator door cover, originally designed as a direct top, the later Division I deepened to a half-cut disconnect, the upper port for stainless steel strip, directly reduce stainless steel loss of about 30%, direct cost savings of 72,000 yuan.

Indoor basin steel frame Division I uses the overall welding system, layer by layer to the upstairs installation, a lot of labor savings, reduce the finished product, indirectly save a lot of labor costs.

4.6

Field examples are listed (drawings deepened).

Smick wall brick loss, original design tender layout Smick wall brick loss of up to 40%, but after repeated communication between the project department and the owner, agreed to adjust the layout, directly reduce the loss of nearly 30%, the on-site loss rate of only 10%-12%. A lot of money was saved.

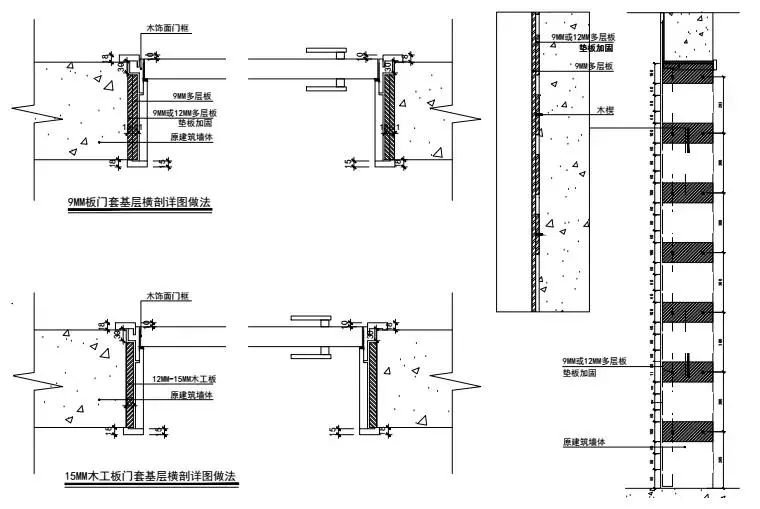

The original door cover grass-roots design for 18MM woodworking board grass-roots is now deepened by division I to 9MM multi-layer board grass-roots, to ensure the thickness of the grass-roots and later quality and grass-roots aesthetics under the premise of reducing costs.

05

Fine decoration to avoid the key analysis

Fine decoration of several important key points control, according to my experience, which is particularly important can be summed up as ‘three defenses’, this ‘three defenses’ for the top priority of fine decoration, avoid not to slow down!

5.1

Anti-aircraft drums

Wall paint cracking, top corner cracking is the most important control point of fine decoration, fine decoration wall roof is mostly a large area of latex paint finish, the grass-roots slightly improper construction, it will cause a large area cracking, resulting in a large area of rework site, to the project brought extremely serious losses.

5.2

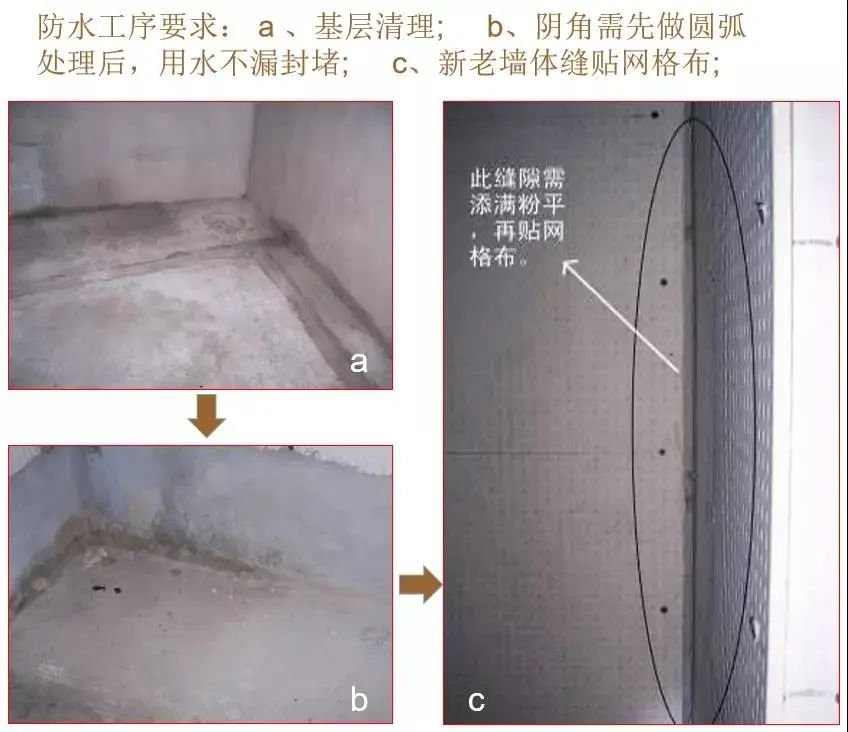

Leak-proof

In the actual waterproofing project, we find that the construction operation factors on the quality of waterproof layer was more and more significant, if the grass-roots treatment, waterproof coating stirring, coating, maintenance, and other aspects of improper treatment, it is very easy to appear waterproof layer cracking, foaming, pinholes, peeling, powdering, breakage and other issues, to the waterproof layer quality has a great negative impact;

5.3

Anti-aircraft drums

Glass brick has become a priority for many owners of surface materials, but glass brick construction is very easy to produce empty drums, fall off and other sites, is a piece of decoration projects over the years, for this reason, your Division has repeatedly formulated a dedicated construction program (back glue process);

The site must be strictly by the technical bottom construction, to avoid the site producing a large area of empty drums leading to rework phenomenon, in addition, the stone empty drum site is also not to be ignored.

06

Transfer notes and transfer products, etc

6.1

The key points of the sub-account acceptance attention

a, in advance to develop the sub-account acceptance plan b, sorting out the sub-account acceptance information

c,sub-house acceptance forms include indoor floor, wall, roof dusting, door, and window project quality sub-house acceptance record form, indoor space size, guardrail, glass quality sub-house acceptance record form, waterproof project, public parts sub-house acceptance quality record form, residential project quality sub-house acceptance summary form, residential project quality sub-house acceptance certificate and other forms.

d, the unity of the pre-construction dimensions, according to the household acceptance plan, unified living room, bedroom, bathroom and other room opening size, such as due to city walls and other reasons can not be unified size, the size changes concentrated to the need to measure the size of the room, such as laundry, kitchen, cloakroom and so on.

6.2

Pay attention to the main points of the delivery room

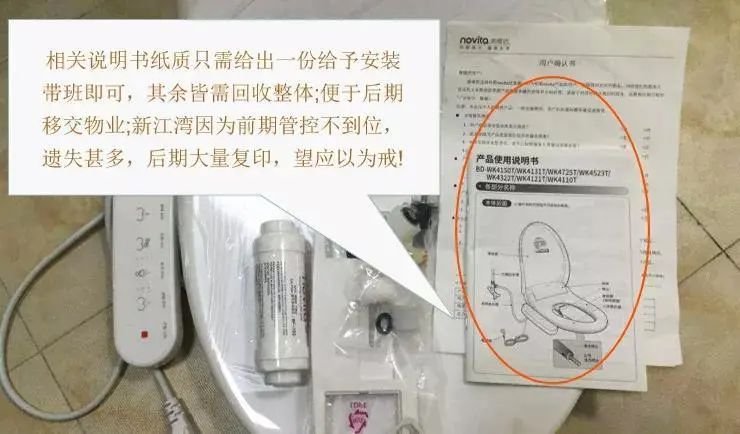

a the construction process of the A supply material information (product specification, warranty, certificate of conformity, etc.) must be well preserved, so that a later family a set of property to be handed over;

b, because the owner requires no defects to hand over the house, from the beginning to organize the property personnel to the completed room inspection, according to the owner’s inspection problems, arrange construction personnel to cooperate with maintenance, repair after the arrangement of property inspection, the average set has been through 3-4 times the property and Party A inspection.

c, related spare materials to hand over to the property, do a good job of written handover procedures, and use PPT for its maintenance and delivery

6.3

Post-repair notes (wood floors).

Wood floor maintenance is a large number of hidden dangers in the late period of fine decoration, mainly divided into the following points:

Case study: the groundwood floor later part of the drum, there is a noise

Cause:(1). Stainless steel closing strip reserve width is too narrow,(2). During the construction of the workers, unsupervised in place, the wall around the telescopic seam was reserved too small. (3) Indoor wood floor area is too large, there is no split shrink seam;

Avoidance measures: factory wooden floor must detect its deformation coefficient in advance (especially 8MM thick laminate flooring), the floor around to reserve less than 5MM telescopic seams, a large area of the site to be laid must be divided into areas reserved telescopic seams (field more than 8M to reserve telescopic seams).

6.4

Post-repair notes (leaks).

Fine decoration room waterproof is very important a division :

Case description: Shanghai Xinjiang Bay later bathroom there is a wall root seepage situation

cause:

(1), the threshold stone under the guide wall due to geo-heating construction slotting, did not do waterproof treatment, resulting in water seepage between health;

(2), ground waterproof in the door cover wall side did not do circumvention measures:

(1), waterproof before the closed water test must be done in place, pipe and yin corner must be checked carefully;

(2), door water stop can prevent damage, waterproof construction must do the outside of the wall, forming a whole waterproof;

(3), through the door stone must cross the bottom to do the wet paving process, to ensure that the bathroom area has waterproof integrity.

6.5

Post-service notes (latex paint wall).

Fine decoration room walls are generally a large area of latex paint finish, if the pre-control is not in place, the latter is very tricky.

There are large areas of cracking on the wall, peeling, and so on

cause:

(1), the pre-wall flour brush ratio problem, not dry on the putty treatment, late temperature changes lead to the mortar layer shrink into pieces, with the surface layer off together;

(2)Improper handling at the junction of one or two structures leads to cracking;

Avoidance measures:

(1), wall flour brush before handling a secondary structure junction, to ensure that the seams are filled with full, wire mesh for joint reinforcement.

(2), wall flour brush mortar ratio must comply with the specification requirements, wall wetting can be painted after processing, in the batch of putty to find a flat party before we must check in advance paint wall is there a hidden danger?

(3), paint too thick place must supervise the construction process to prevent workers from forming once, to layer paint.

The decoration and decoration process will appear a variety of questions, the reason is nothing but materials and technology! As long as the construction before the reasonable design, in the construction of all links to achieve layer control, can ensure the overall quality of the project, as far as possible to achieve high-quality construction.