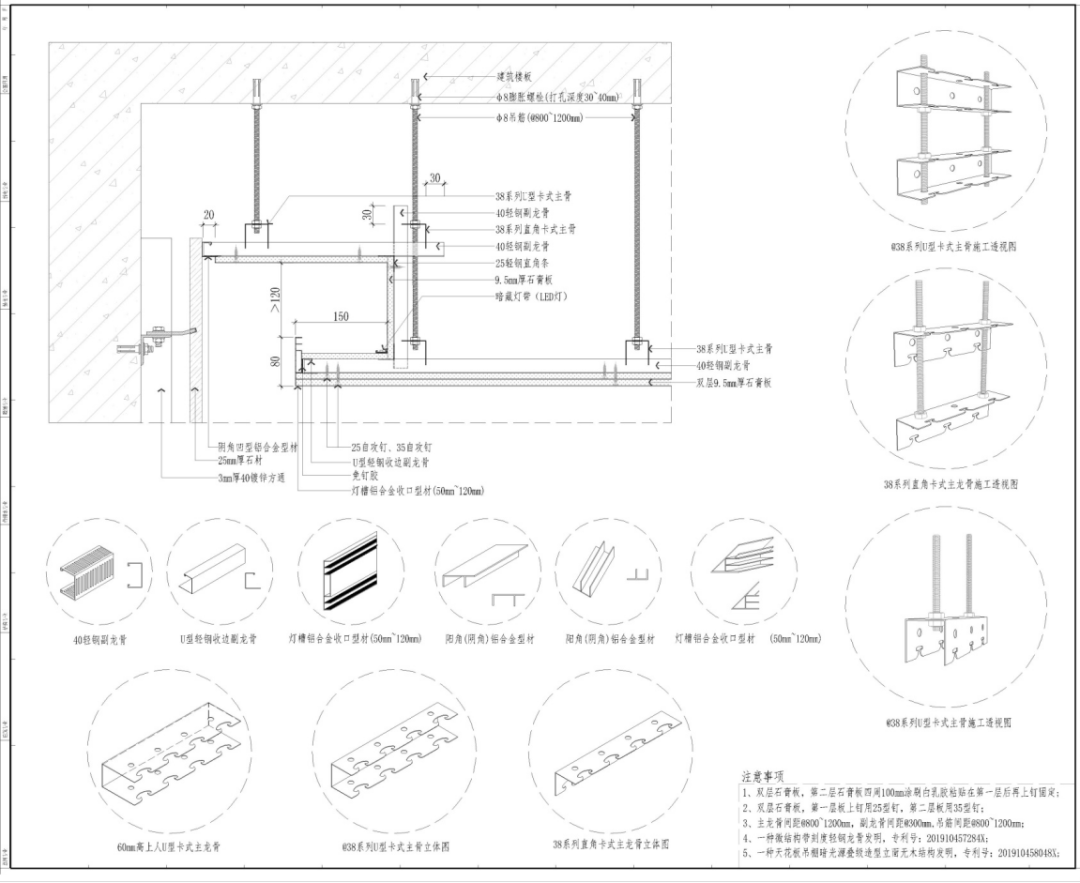

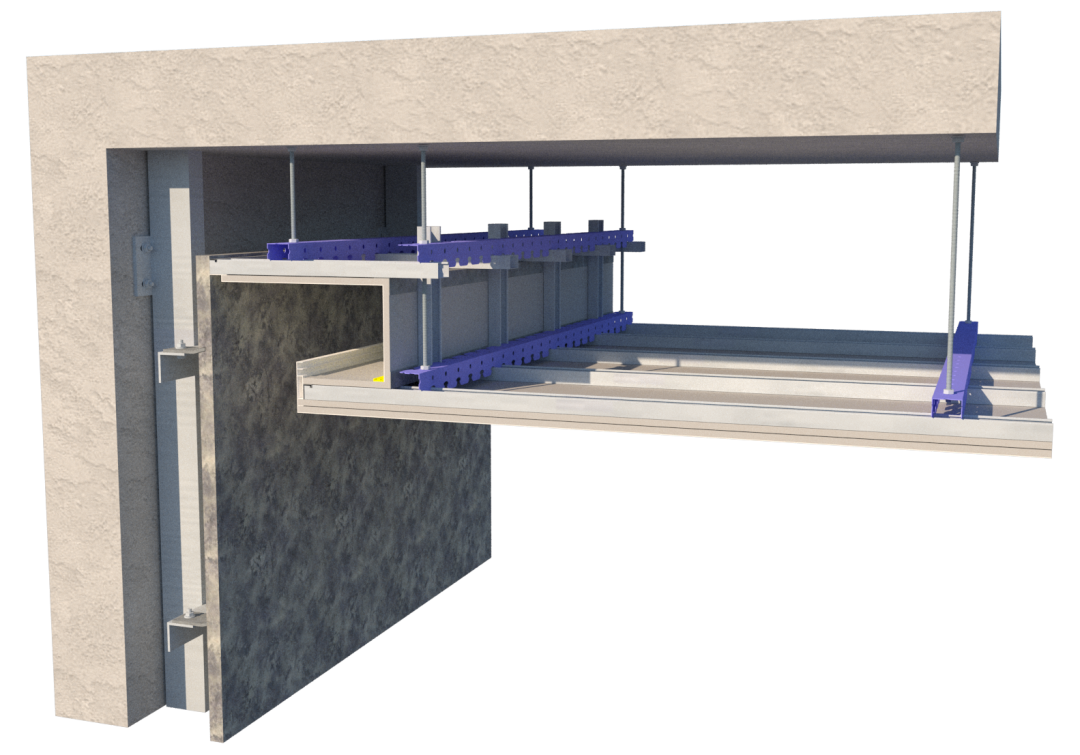

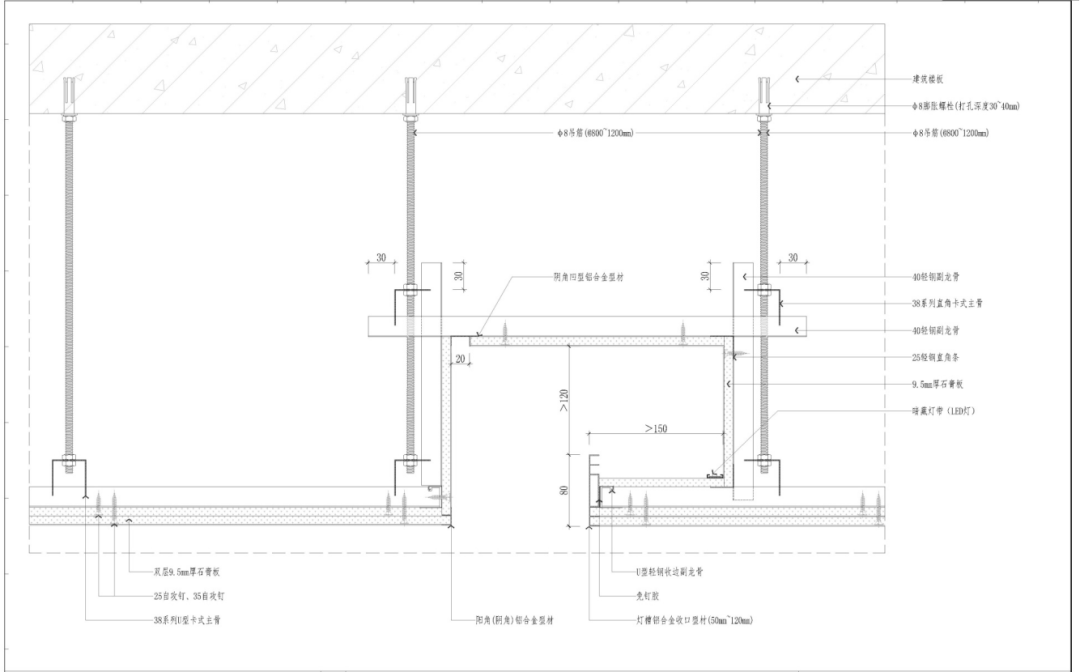

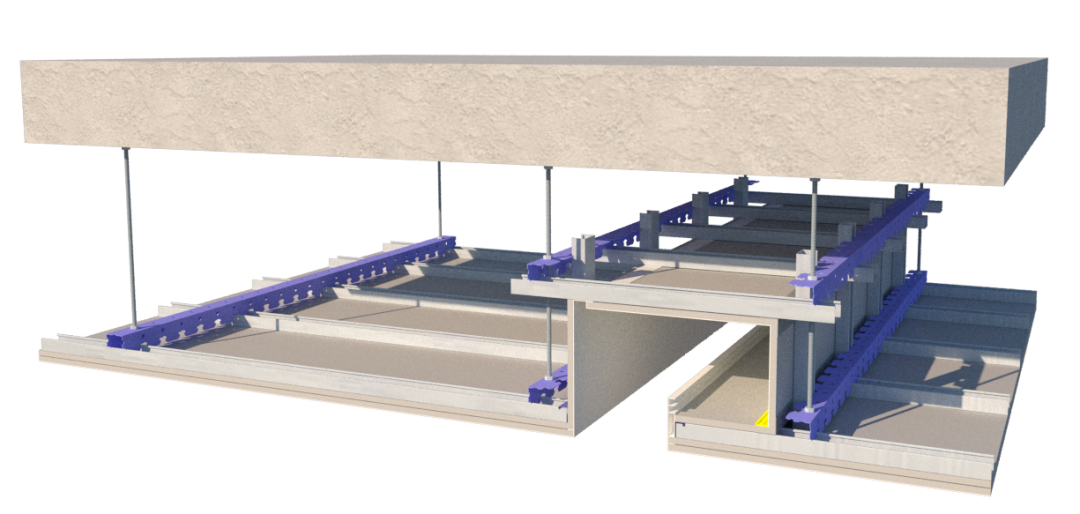

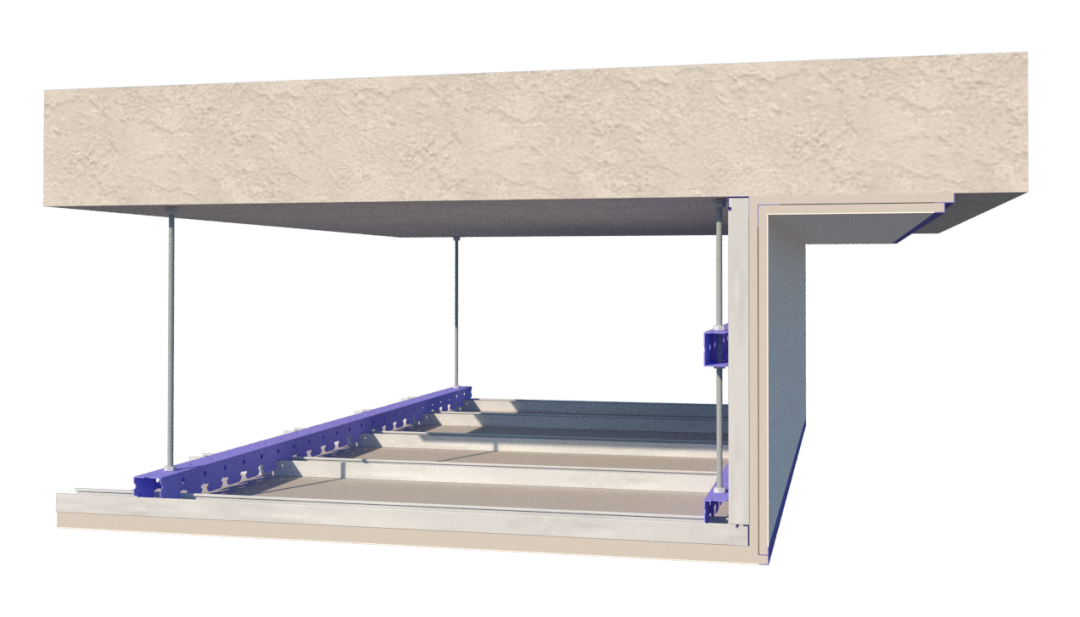

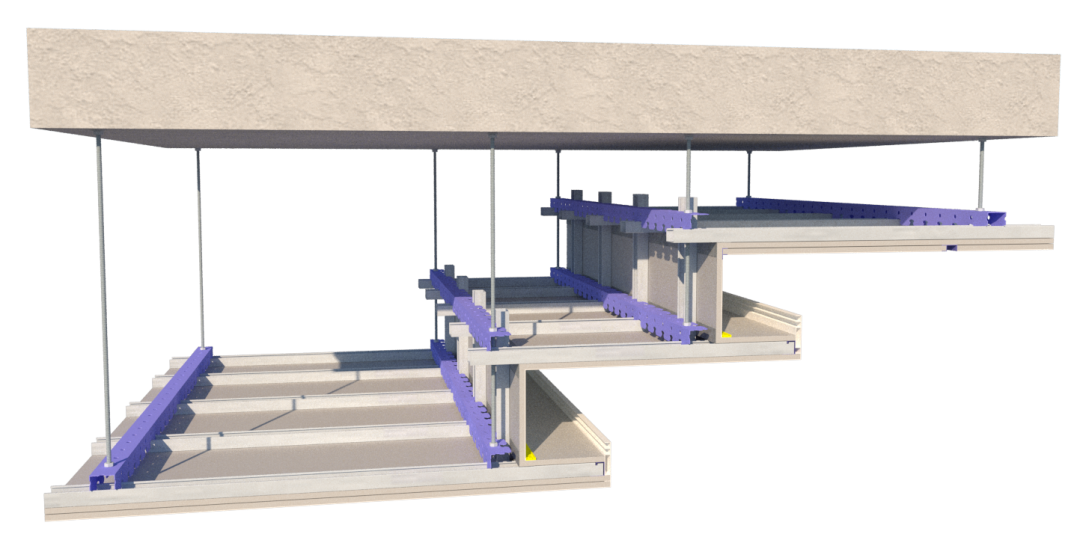

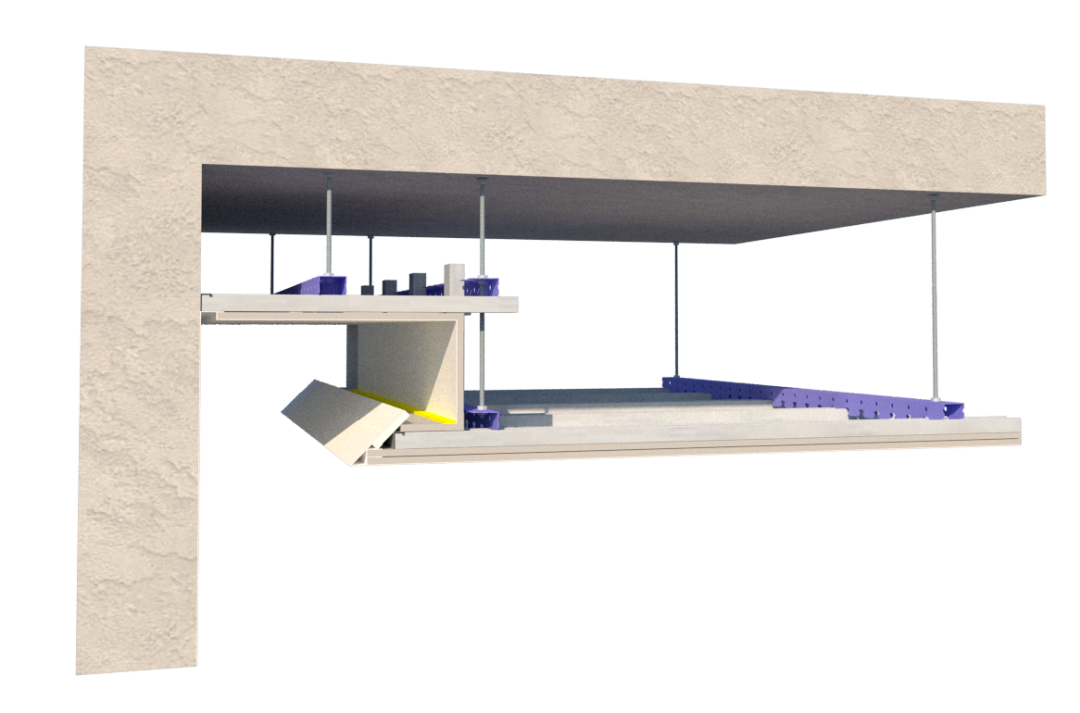

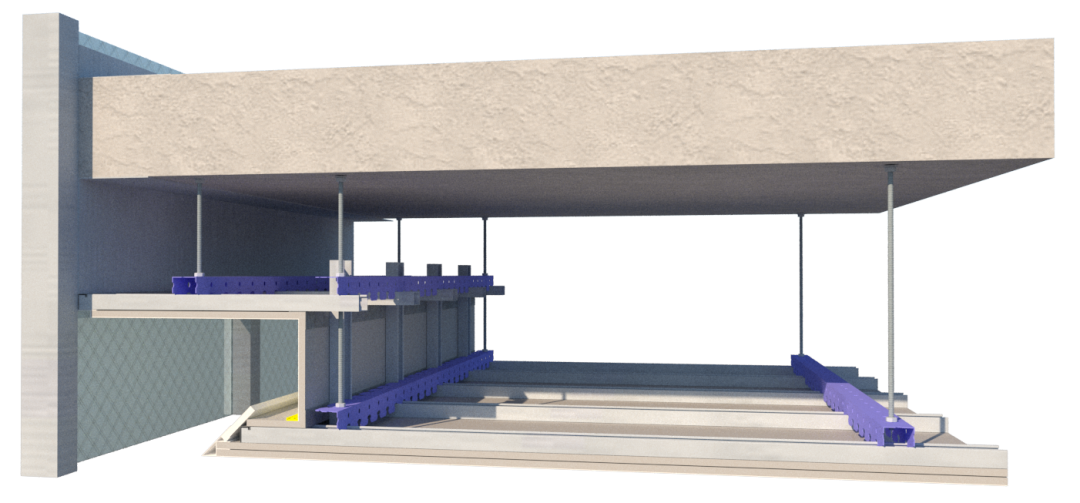

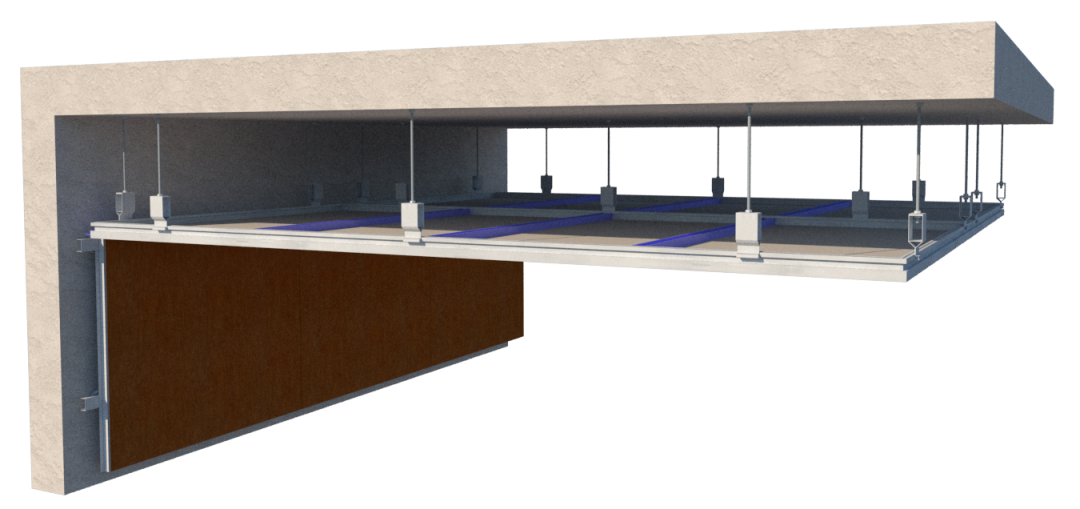

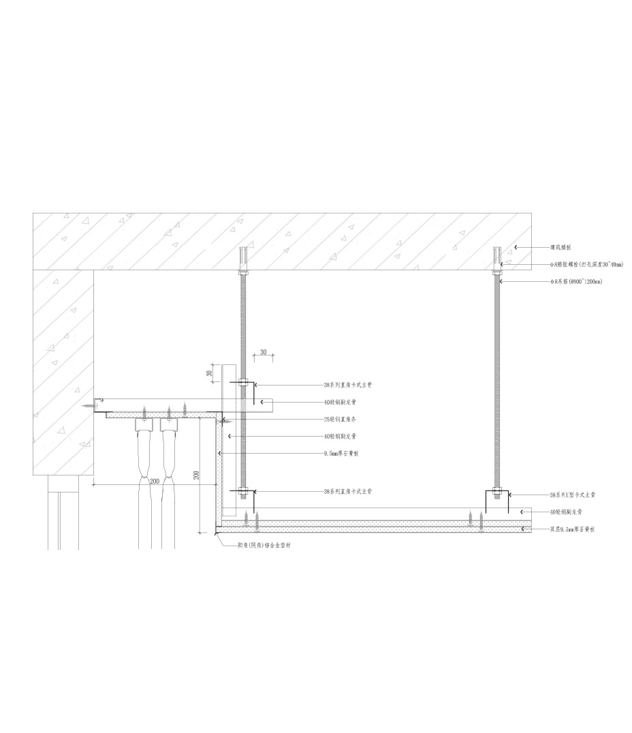

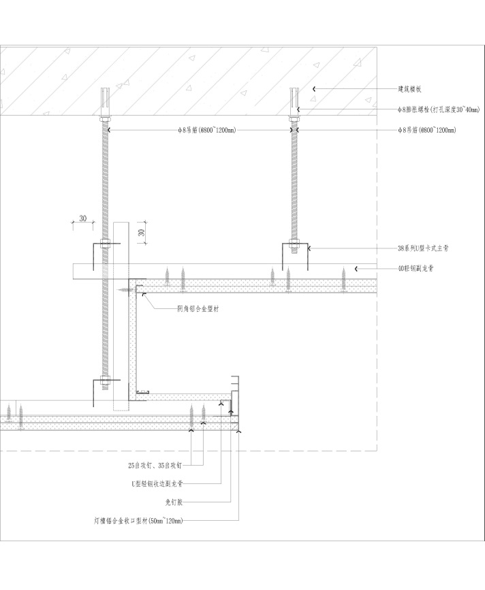

Full light steel keel structure ceiling stacking process node, three-dimensional illustration.

In the high-end hardcover project, the standard practice of all-light steel dragon construction has been very mature, and the traditional process site construction a large number of use of wood keel grass-roots, flame retardant plate grass-roots, density board grass-roots, carpentry board grass-roots, and other practices, quasi-, fine, assembled, light steel whole keel Construction standards and design will be more conducive to project cost control, design quality control, construction cycle control, to make the cost-effective civilized site.

However, due to the influence of long-term traditional concepts, most decoration workers are accustomed to the use of wood grass-roots practices, can not change the concept for a while, the habit of thinking that the use of “all-light steel keel” construction will be slow, the cost will increase it is not.

Factory custom assembly transport to the site construction of the “all-light steel keel” structure, can achieve rapid installation, greatly shorten the installation time, also reduce labor costs and material costs in general, the full light steel keel standard did not increase too much cost, but to improve the quality level of the project.

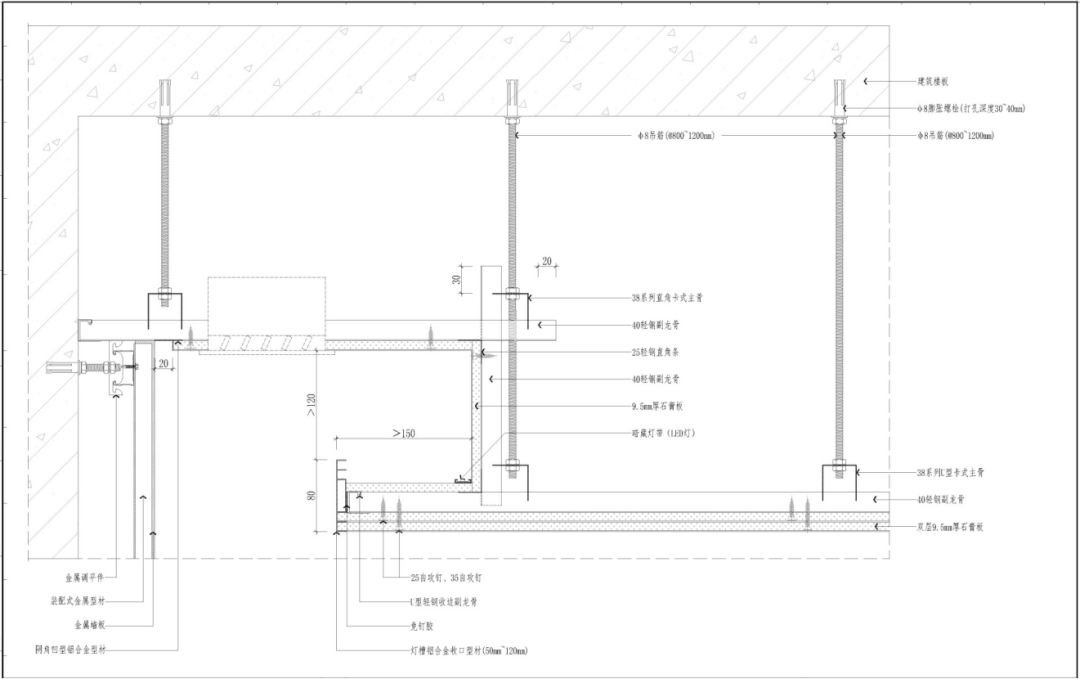

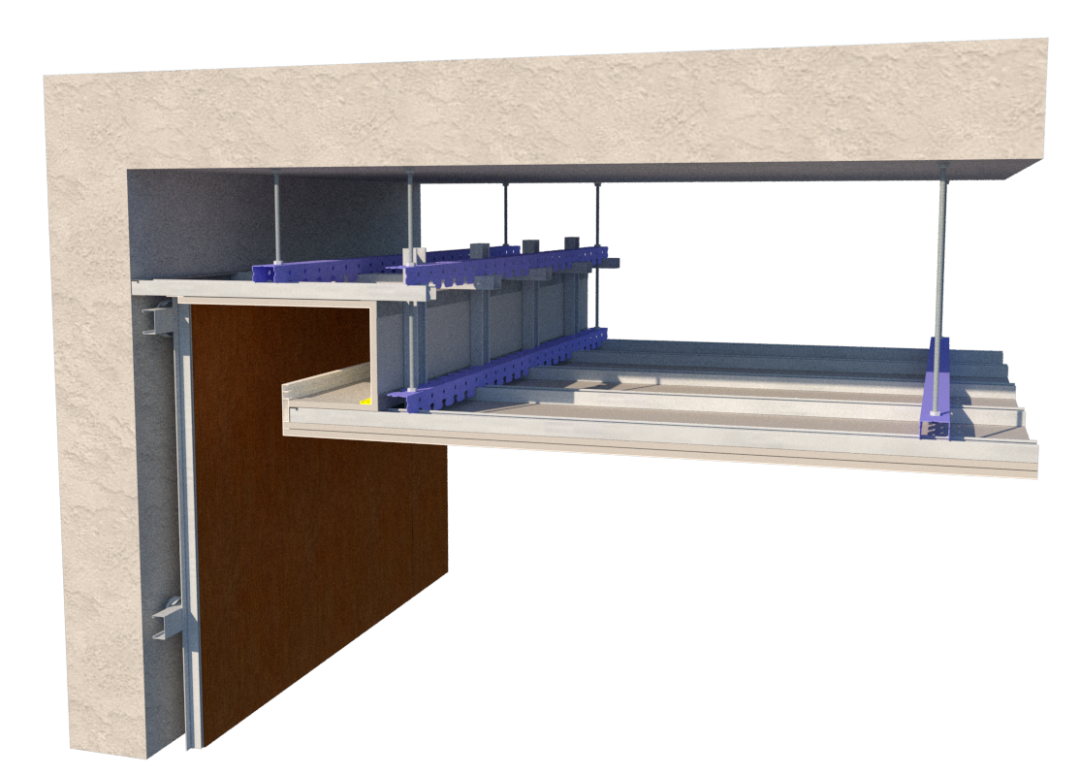

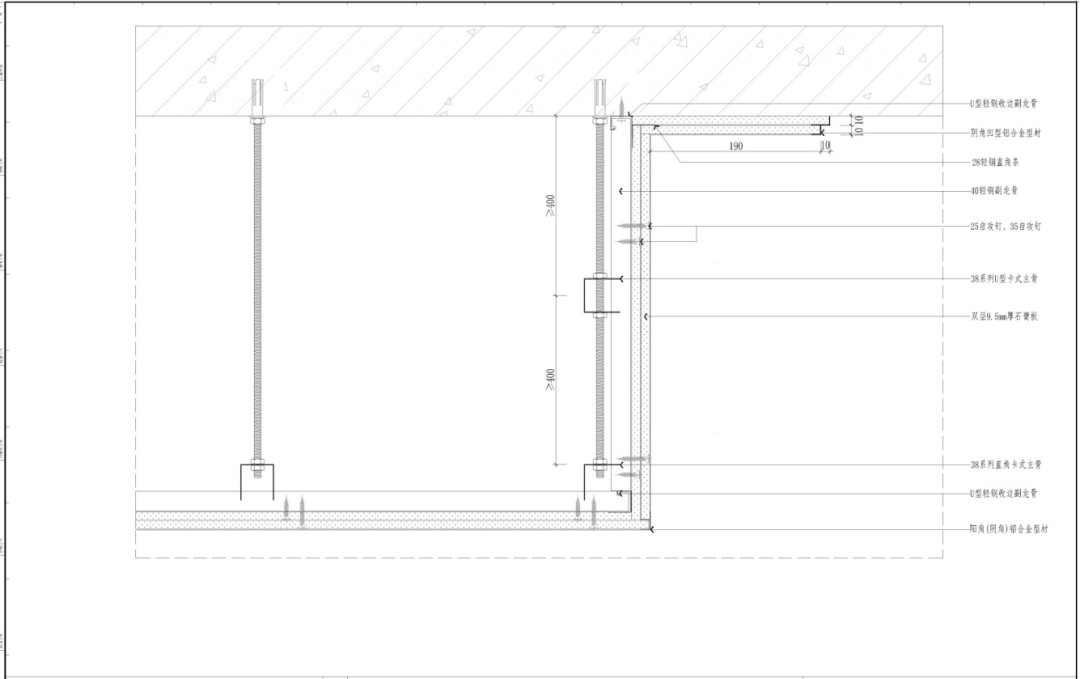

Below we introduce the project fire-resistant light steel keel structure ceiling stacking universal node.

01/ Assembly decoration is a difficult problem

- Human level: project managers lack of industrial thinking, dare not boldly innovate, still retain the traditional construction methods, in the risk of new technology is not carefully measured and compared;

-

- Architecture and decoration level: at present, the domestic building module and decoration module is not coordinated and unified, there are differences;

-

- Technology and materials: the current situation is a thousand people, each company is in the new, but each material specifications and technical standards are different, although the general direction and technical effects are consistent, but the specific way of construction is significantly different, this promotion market and market inspection bring difficulties;

-

- Project assessment: At present, there are more domestic project assembly-style construction projects, decoration indoor projects are relatively few, so to a certain extent lack of inspection and recognition of the owner of the conditions.

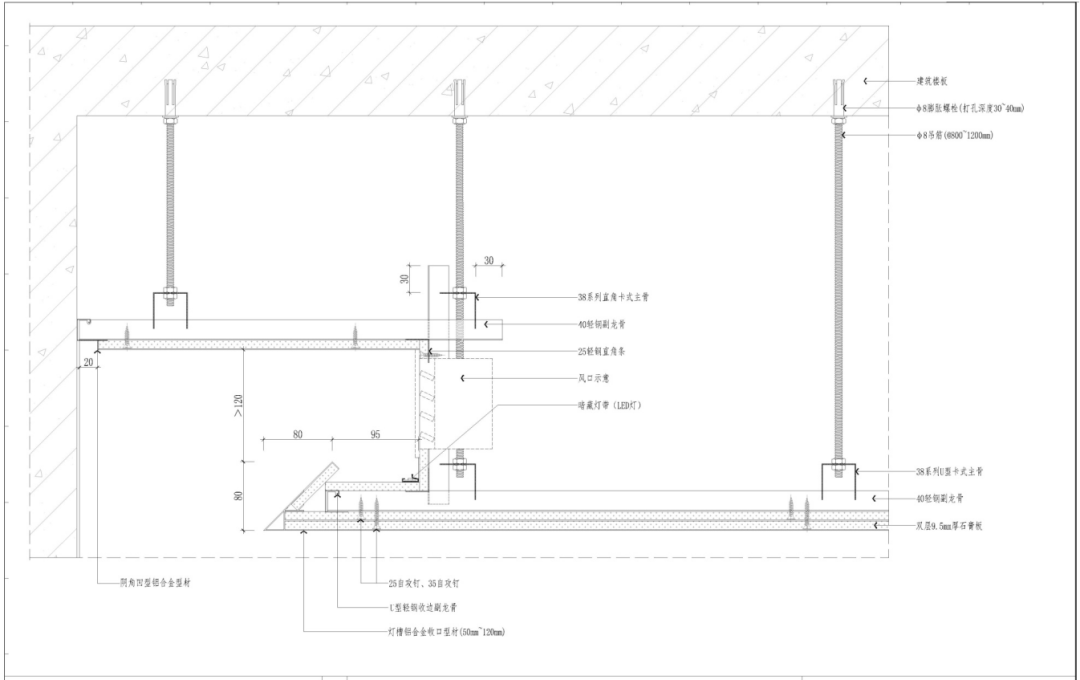

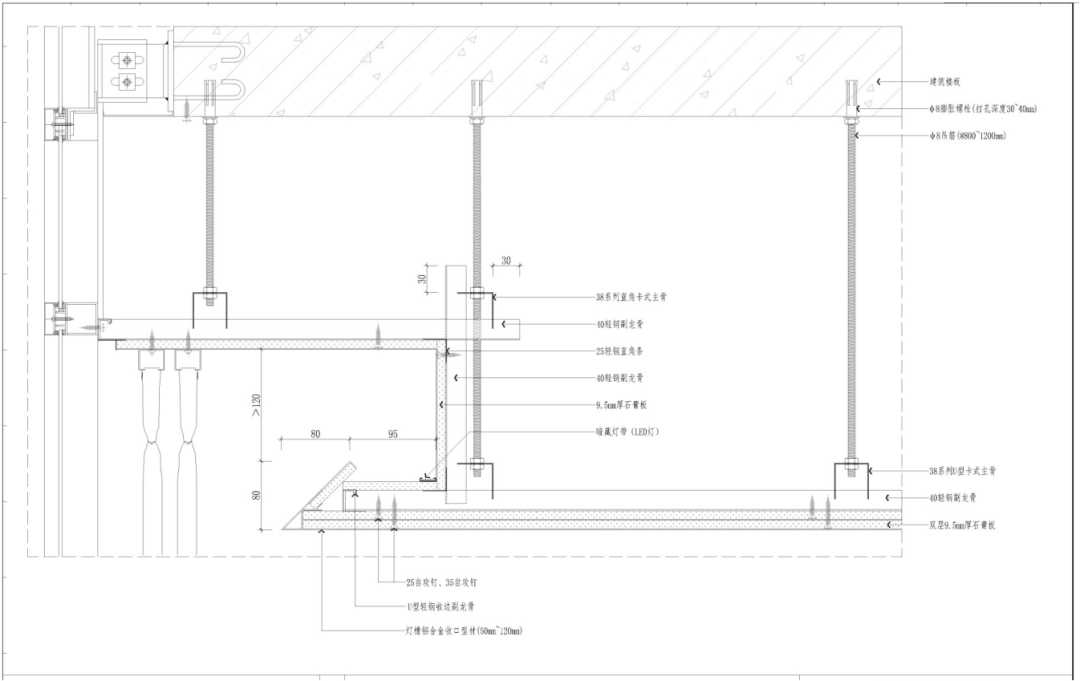

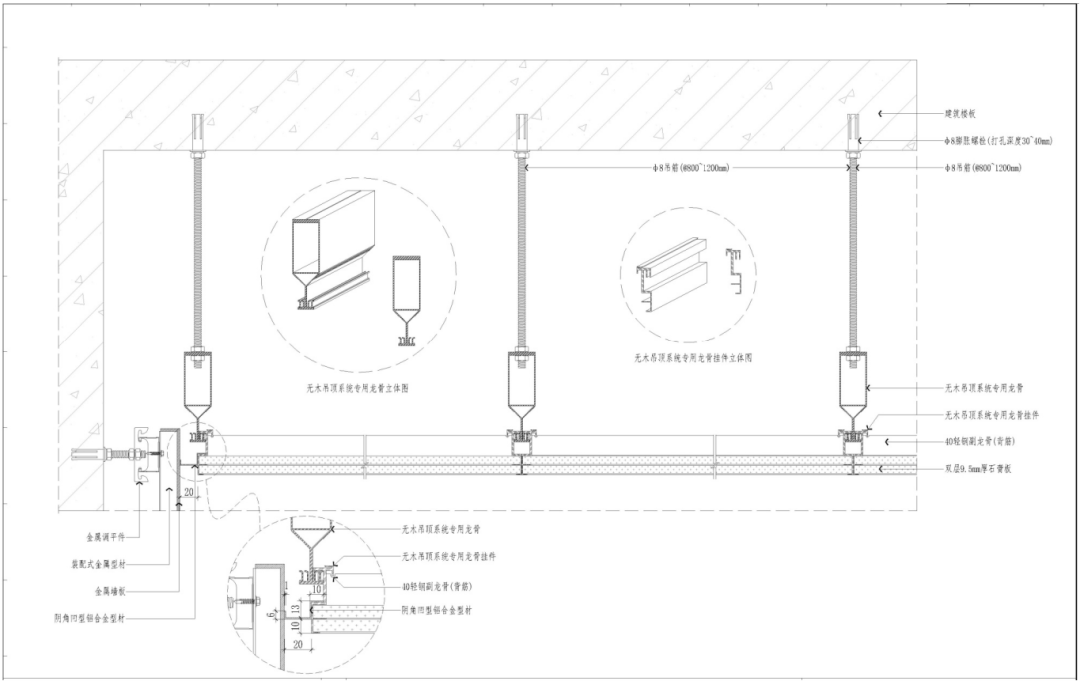

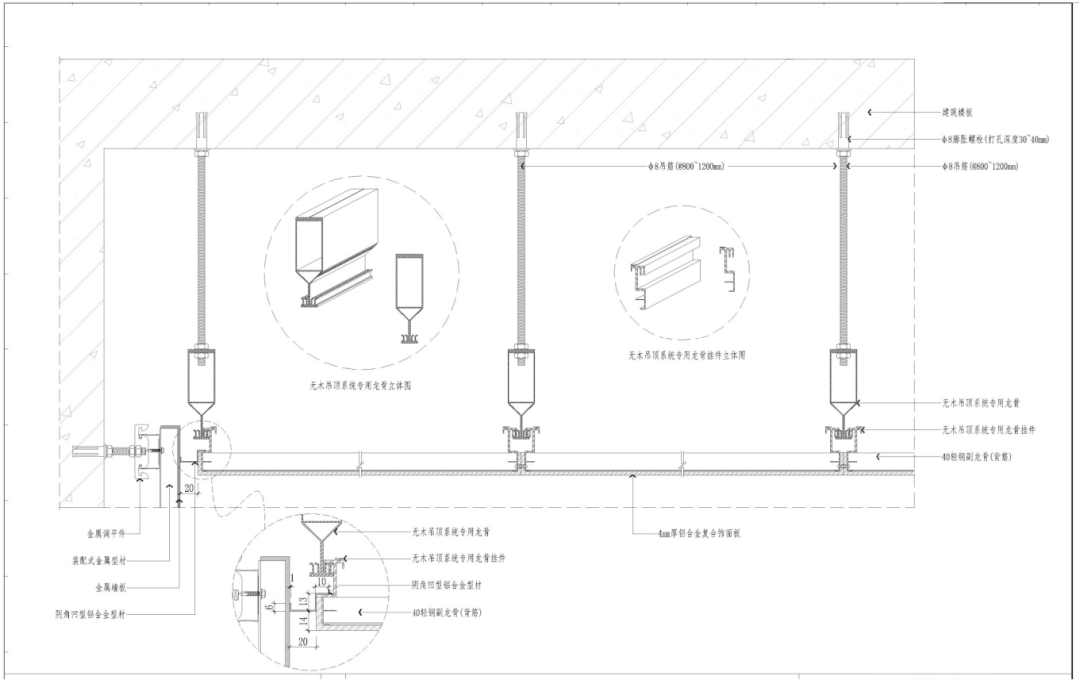

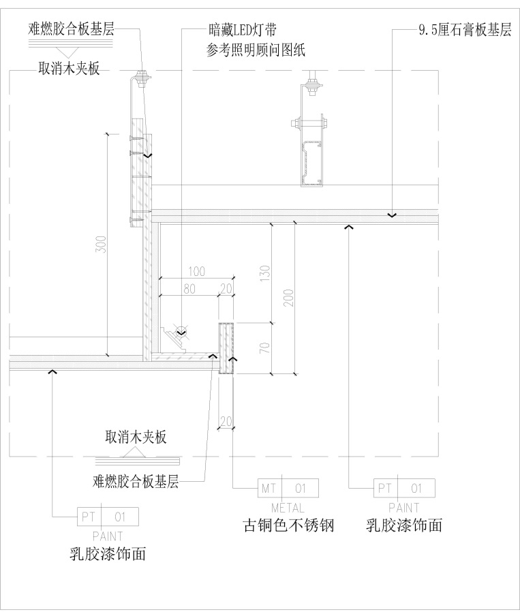

02/ Drawing resolution

Woodless smallpox assembly main accessories

03/ Cost Analysis Case Description

In this case, the standard hotel room area is 37 square meters, the decorative ceiling finish surface is 2600mmhigh, ceiling curtain box and ceiling hidden lamp belt stacking level can save 8.3 square meters of reusable plywood, according to E0 level 12 percent hard-to-burn plywood market price, per square meter of non-combustible plywood can save 50 yuan, a total of about 415 yuan of material costs; 1 to 2 labors.

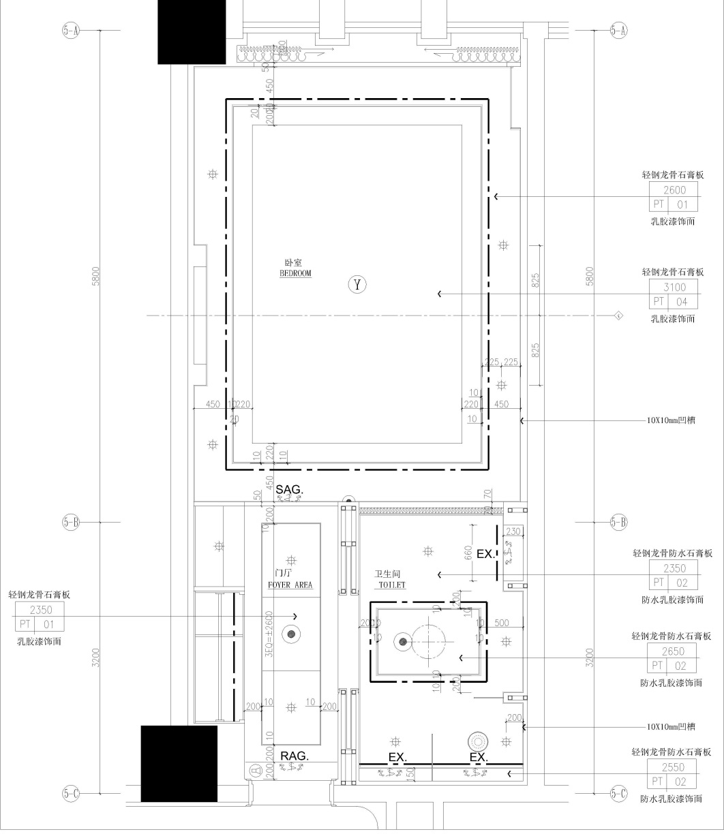

Standard room floor plan

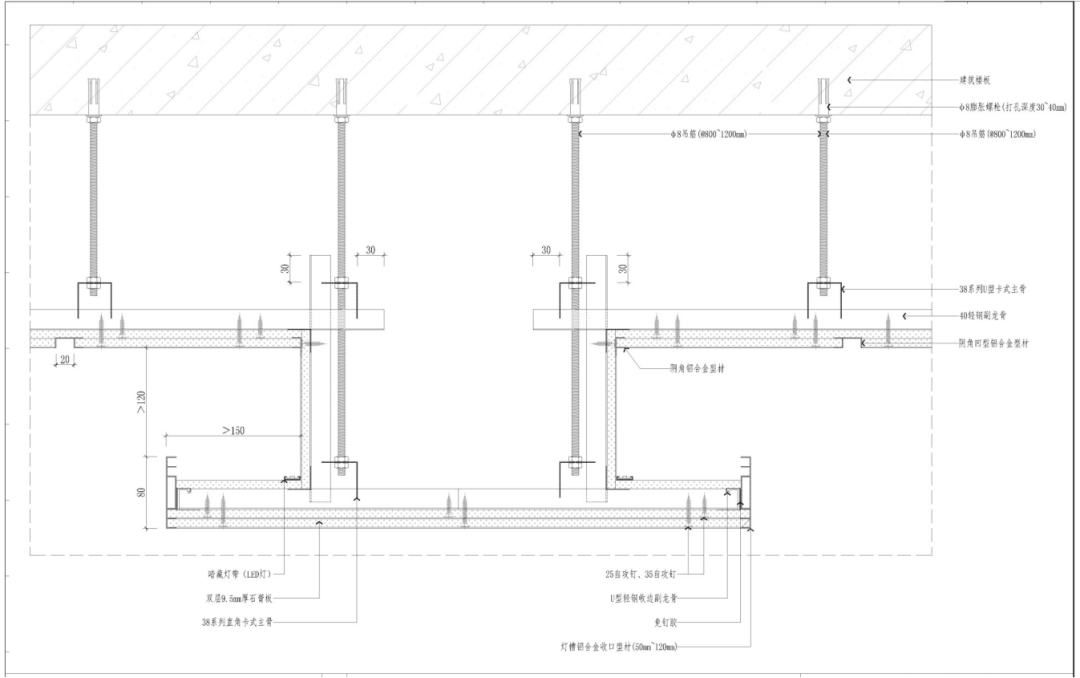

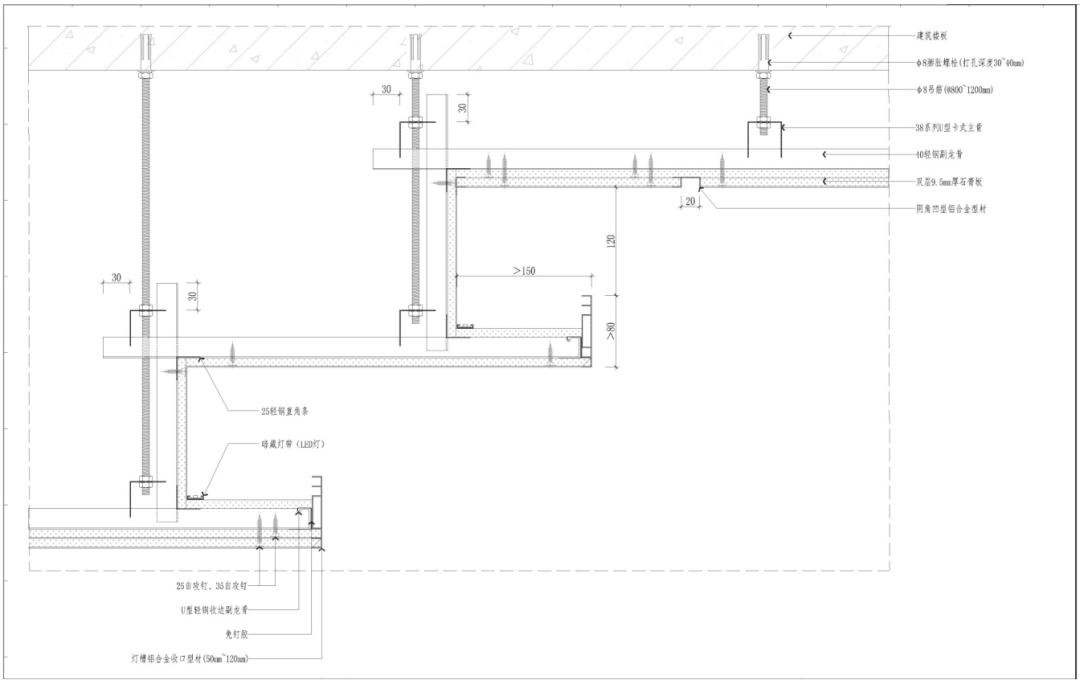

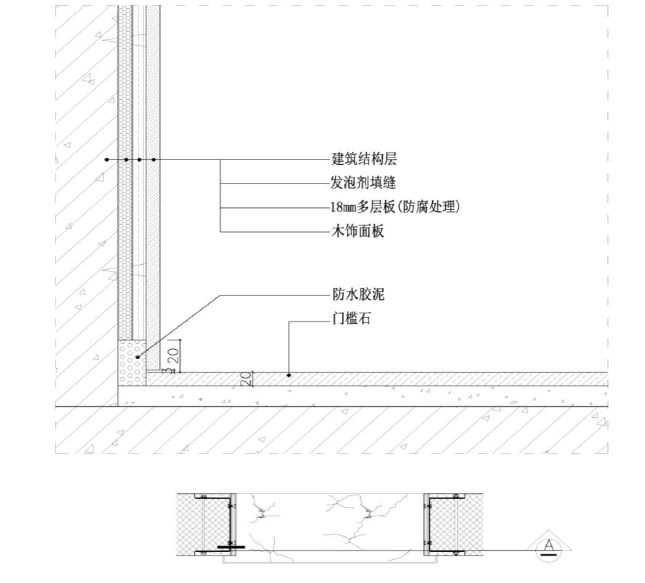

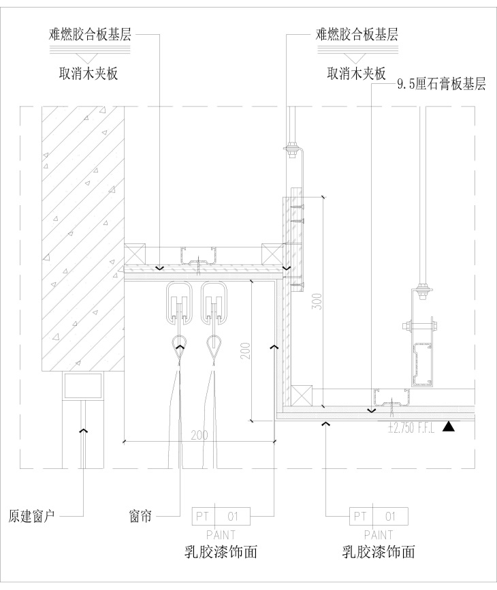

Curtain box node / wood-free curtain box node

Lamp slot stack node / wood-free lamp slot stack node

Ceiling curtain box shape cancel the original design drawings hard-to-burn plywood base, the use of wood-free light steel keel ceiling can save the area of the wooden splints is:500 x 3550 x 1 .8m 2 about 0.6 splints.

Ceiling lamp slot stacking level modeling cancels the original design drawings hard to burn plywood base, the use of wood-free light steel keel structure superposition ceiling can save the wood splint area of (300 x 14202.7),(150 x 14202.7) About 2.16 splints.