Construction management, management core, decoration construction 0-100 whole process control system

How does an excellent project manager develop a division of work, plan to review and operate ideas to ensure that the construction site budget, materials, construction, deepening, quality inspection, safety, and other 7 positions can do their jobs, reasonable staffing, the formation of regional management model?

Don’t worry, the following detailed (juggernaut) standardized construction planning “0-100” whole process guidance worklist, can help you, specifically to “material work”, “deepening work”,” Project management, project progress control, quality control, several points to expand:

01

The preparatory phase for the start of construction

Before the project enters the market to start, the company is in charge of the leading organization to start four exchanges and form the bottom minutes.

1.1

Start the delivery of the bottom

Four cross-ends

(Design, marketing, tender, contract)

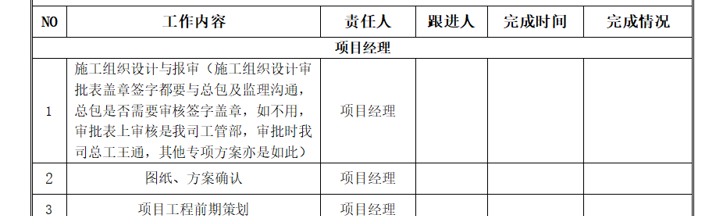

Identify 10 days,30 days after entry The division of work that the project department must complete.

Project Department to develop quality, management, duration goals, team goals, and form a written document, implemented into the project management planning.

1.2

Set goals

Quality objectives

1, the company’s goal:

(1) Establish a strategic partnership with an owner

(2) to make the company’s fine decoration model room project

2, project heading:

Internal inspection of more than 91 points

3, team construction objectives:

The quality of stone and wood finishes shall not be lower than the construction process and closing quality standards of a certain project.

Business objectives

1, contract control with the owner

2, team contract signed

3, materials manufacturer contract

4, deepen the design

02

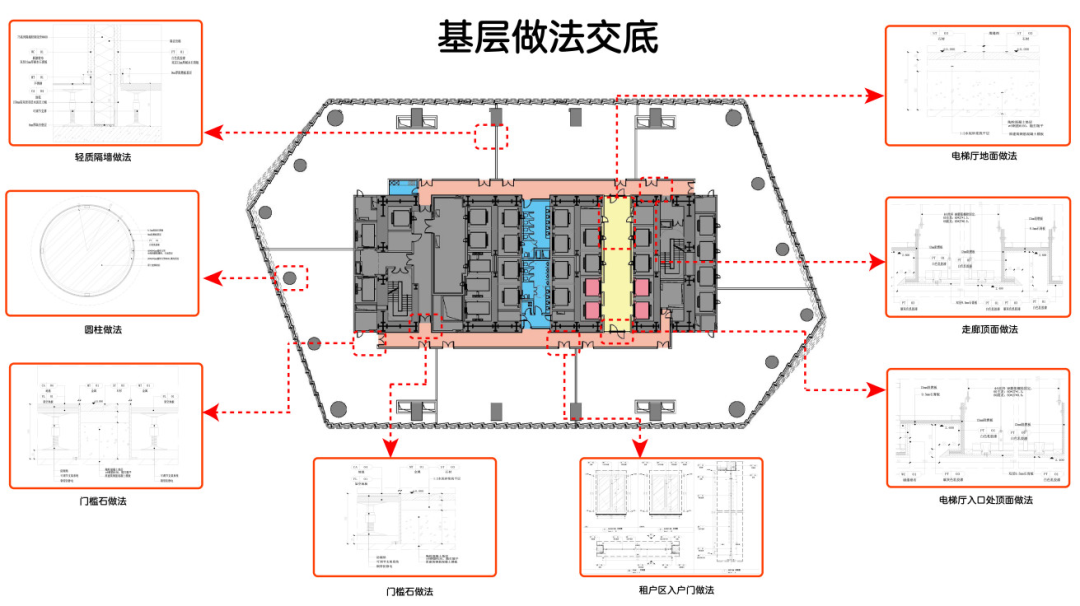

Grass-roots construction phase

Today we talk about the product, it is no longer the Internet circle product manager’s hot word, the meaning of the product has become more broad, in the field of decoration there are also several special product managers in the decorative control process, production module “productization”, that in the final analysis, What is a product-based decoration?

2.1

Product planning

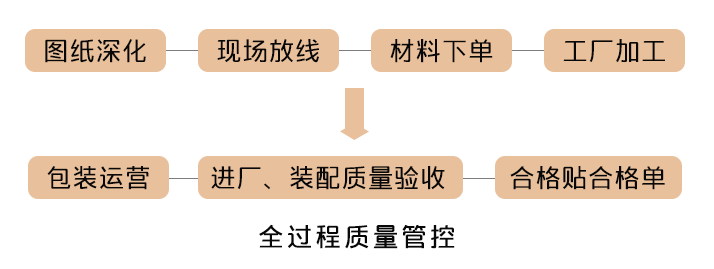

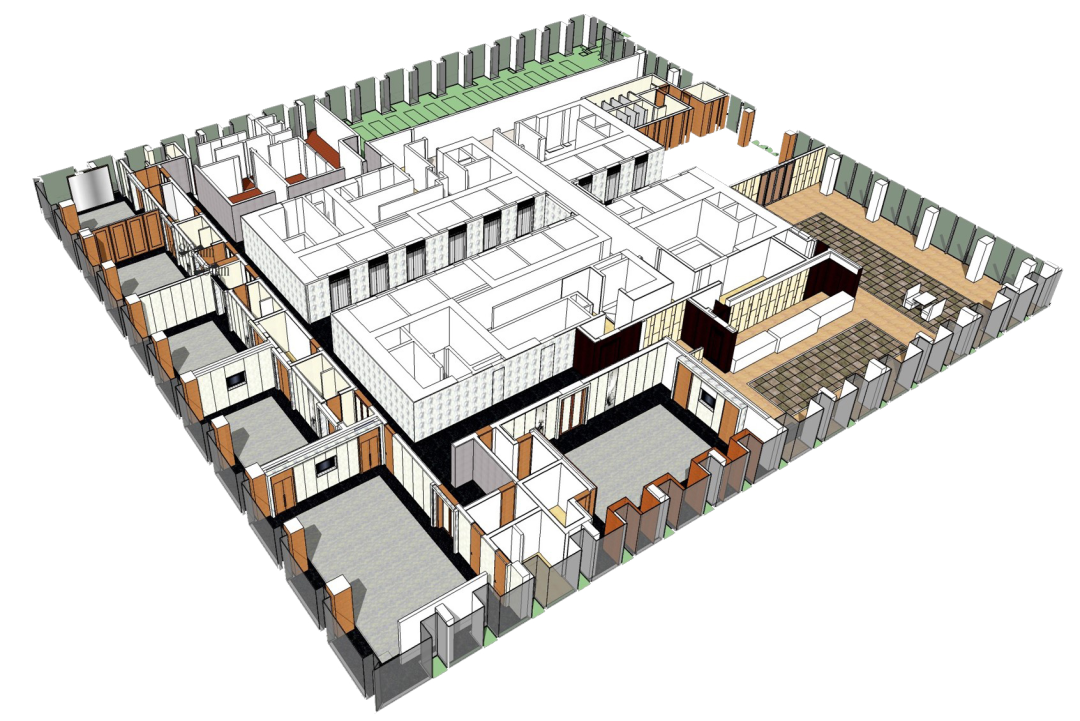

Productization refers to the decomposition of the various components of the project into easy-to-process or uniform specifications of fixed parts (parts are products), each component through distribution, assembly, quality inspection, packaging to form a complete product construction process. Productization engineering refers to the project integrated by mass production and processing means.

Simply put, it is in the process to emphasize the production mode, and modular standard parts to assemble products, modular assembly to form a decorative product.

Factory pre-processing, on-site assembly…

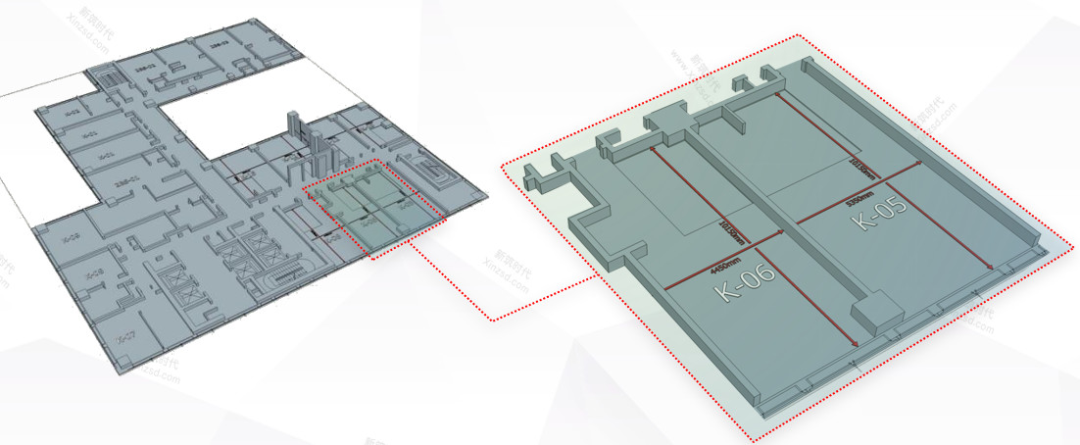

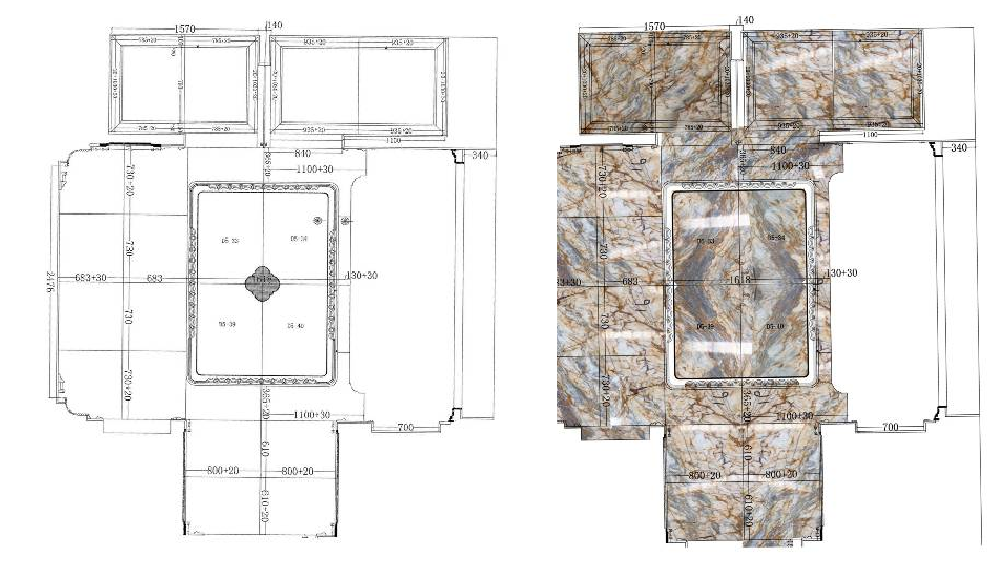

Productization puts forward higher requirements for the early work such as deepening and line release. The traditional sense of extensive line, increasing the size of the field cutting method, has been unable to meet the requirements of product decoration, deepening program needs to be finer, more accurate size, more careful material. “Concentrate the line, fine deepening”.

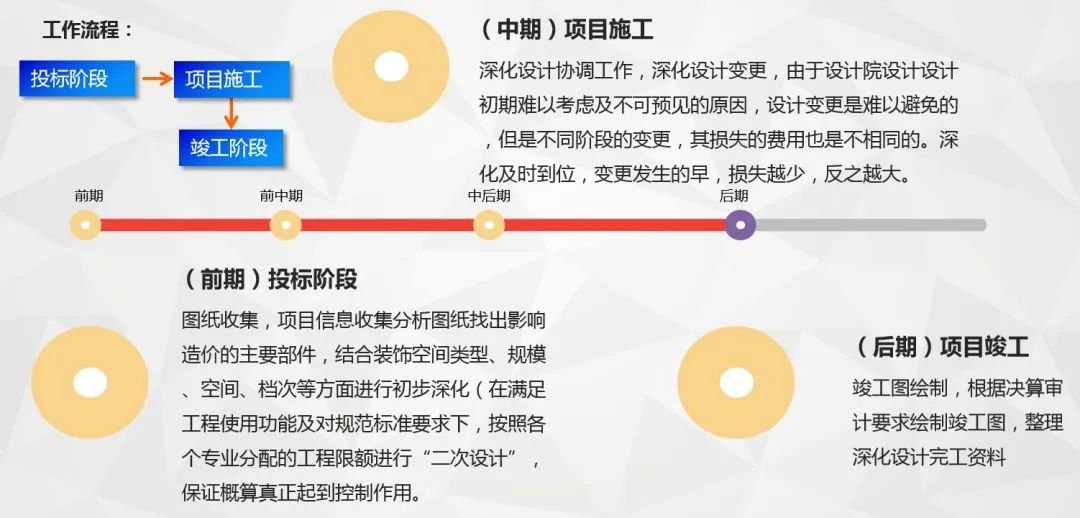

We first from the important process management of deepening design to take everyone to a complete deepening with the project of a full process, and now, deepening has become a bridge between design and engineering, to ensure quality, progress, and cost of an important link.

2.2

Deepen the design of the whole process management

Deepen the workflow of your design

2.2.1 What do I need to do to deepen in the early stages of a project?

1, full participation in the drawing triage

Drawing triage work should be fully involved, to avoid the completion of a single post. Early detection of problems in the full review map can effectively reduce losses. It is also an important way for project management and effective learning.

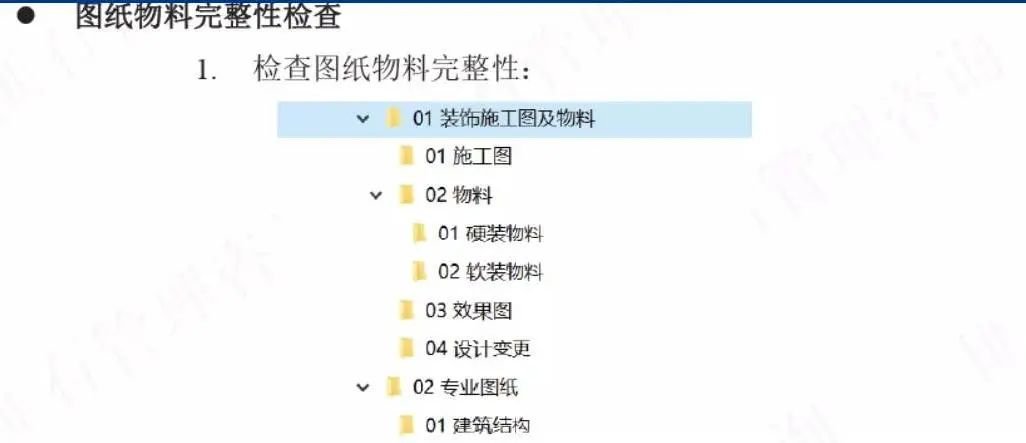

2, drawing material integrity check

Collect complete drawings for the next drawing review.

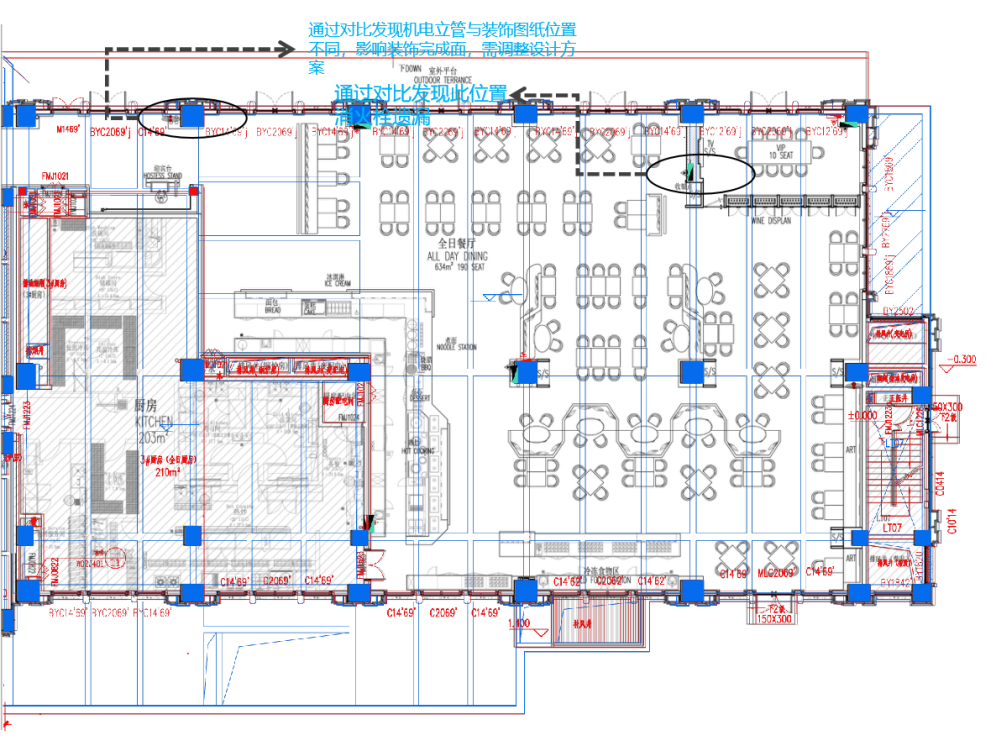

3, site survey

Master the site civil masonry, mechanical and electrical drawing version, check the site masonry wall mechanical and electrical pipe and decorative drawings consistent.

The high implementability of walls, curtain wall positions, mechanical and electrical pipes, and ceilings are measured by the baseline.

4, the work interface division

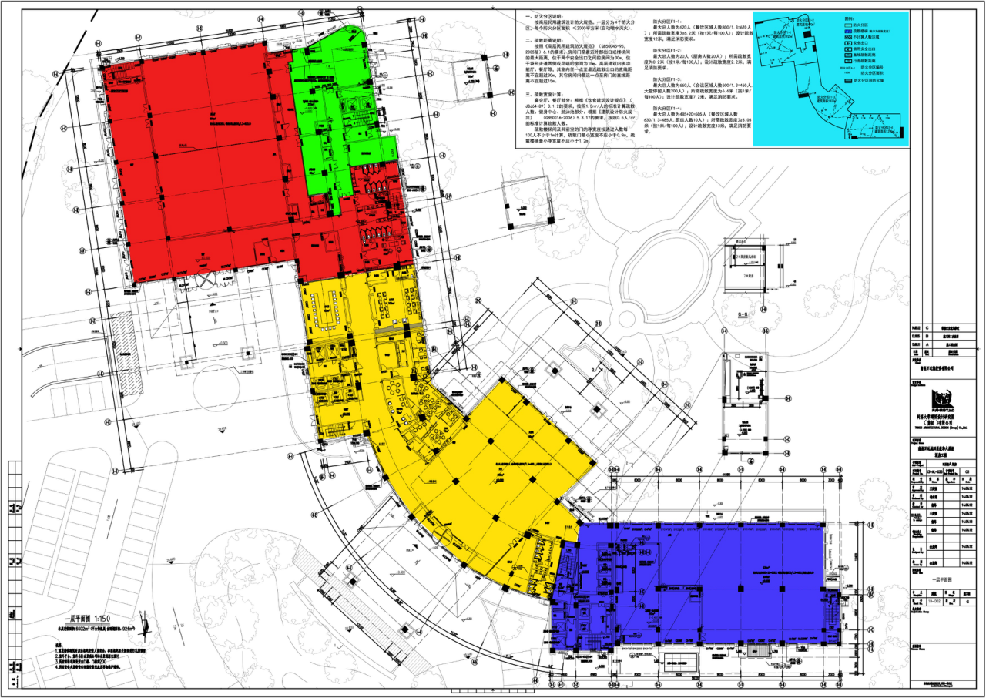

Check whether the contract, list, drawings on the work interface description is clear, especially in the multi-standard area work, strong and weak electric work interface, front and rear field area division is often difficult to define clearly through the text description, can be confirmed by CAD color plane form with the owner.

5, professional drawings of the system review

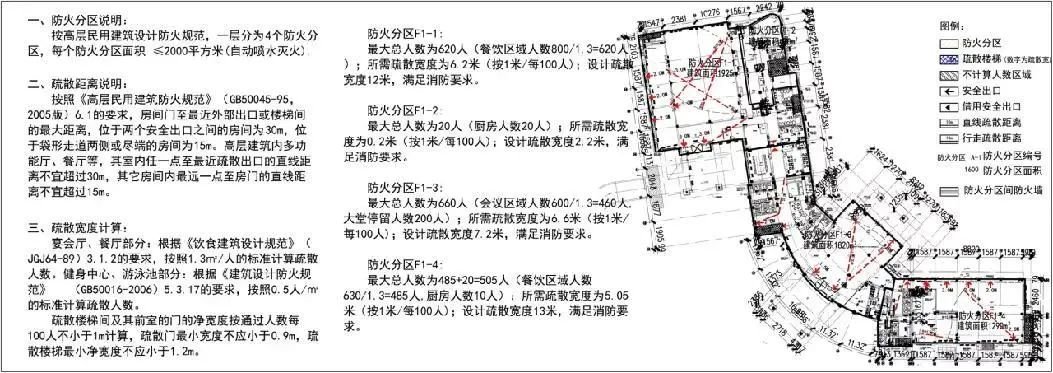

Fire zoning map: View the building map fire partition division, firewall, fire door, fire curtain setting position, and decoration drawing check.

Fire evacuation

Anti-smoke partition

Building walls

Check the position of the beam and the point relationship of the watering equipment

Check the location of the kitchen, bathroom drop-off area

The position of the electromechanical fire hydrant

Check the water supply and drainage drawings fire, water pipe position

Check the electrical drawing box position

2.2.2 What is the work done during the construction phase of the project site?

Through the drawing triage, organize the following list:

1, drawing answer list

: With the project department, explain, Party A, the designer’s intention, and the drawing triage in the problem, clear which is the construction staff to solve the problem which is to deepen the design of the deepening of the drawing, responsibility to the person.

– Answer questions at the scene of the question-and-answer session in places where the location of the triage of the drawings is not clear, to avoid forgetting later.

2, special program deepening list (rationalization proposal).

Stone lines, gypsum lines, stainless steel lines should be combined with node charts and quantity classification statistics, the need for multi-professional integration of special deepening: such as service desk, revolving door, door partition, fire curtain door.

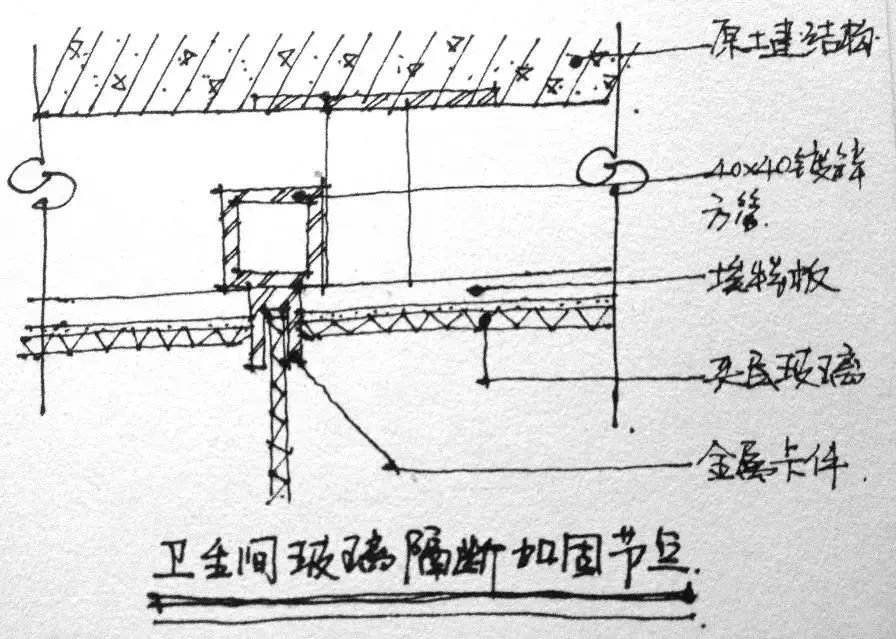

Original design node problem: urinal break should not be directly fixed only in the grass-roots board, insufficient firmness, there are security risks.

After deepening the node recommendations: Metal pieces fixed to the base steel frame (where the appearance is feasible) to ensure the safety of the use of glass partitions.

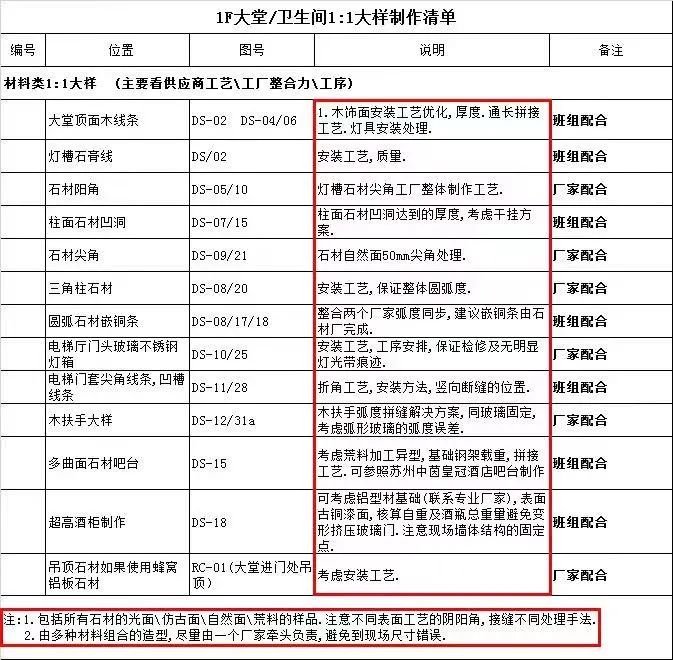

3,1:1 sample list

With the project department to optimize the original design modeling, account for clear the various materials between the closing scheme, and make a big sample.

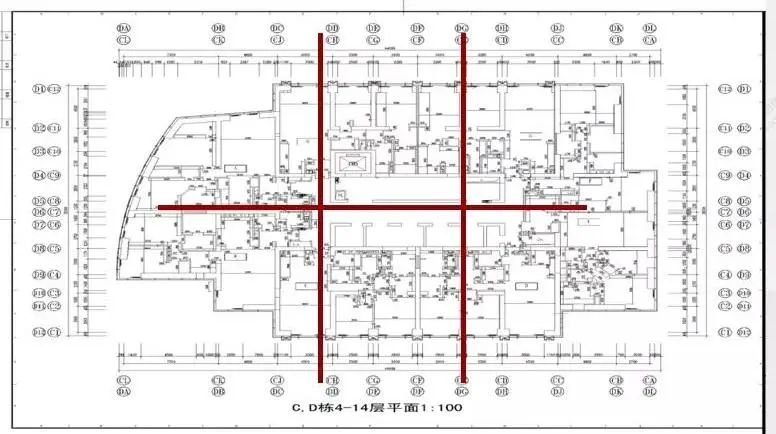

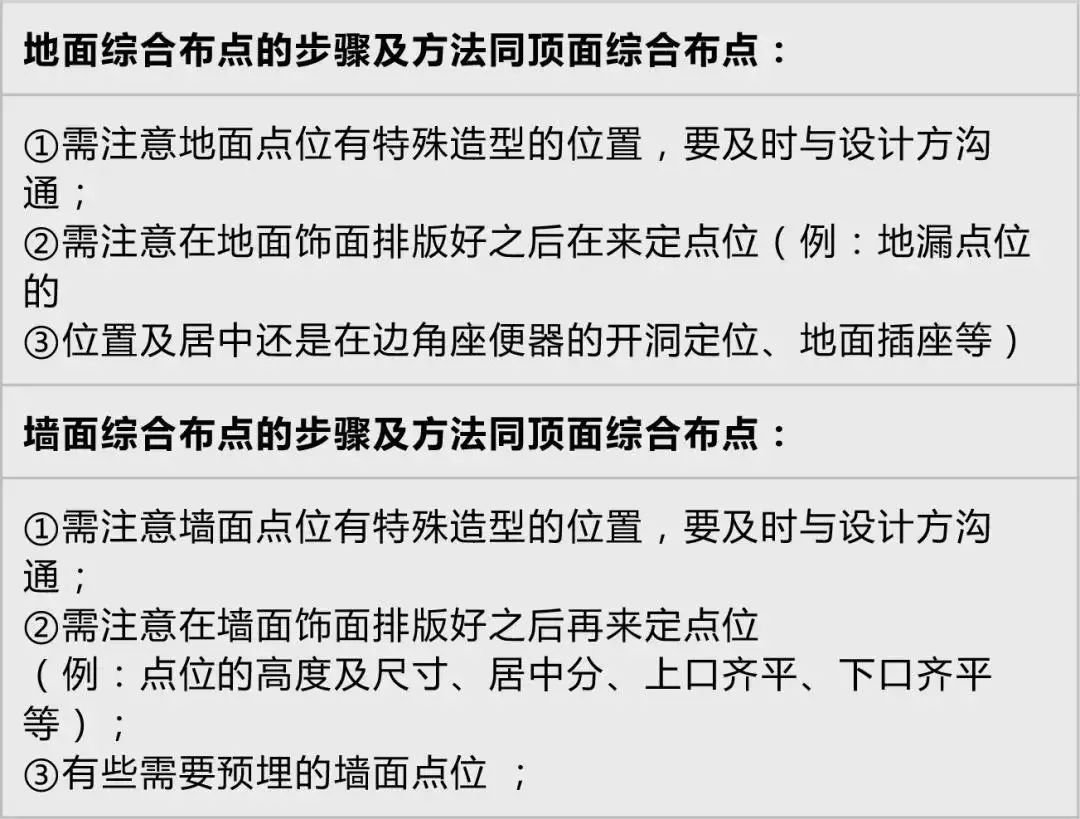

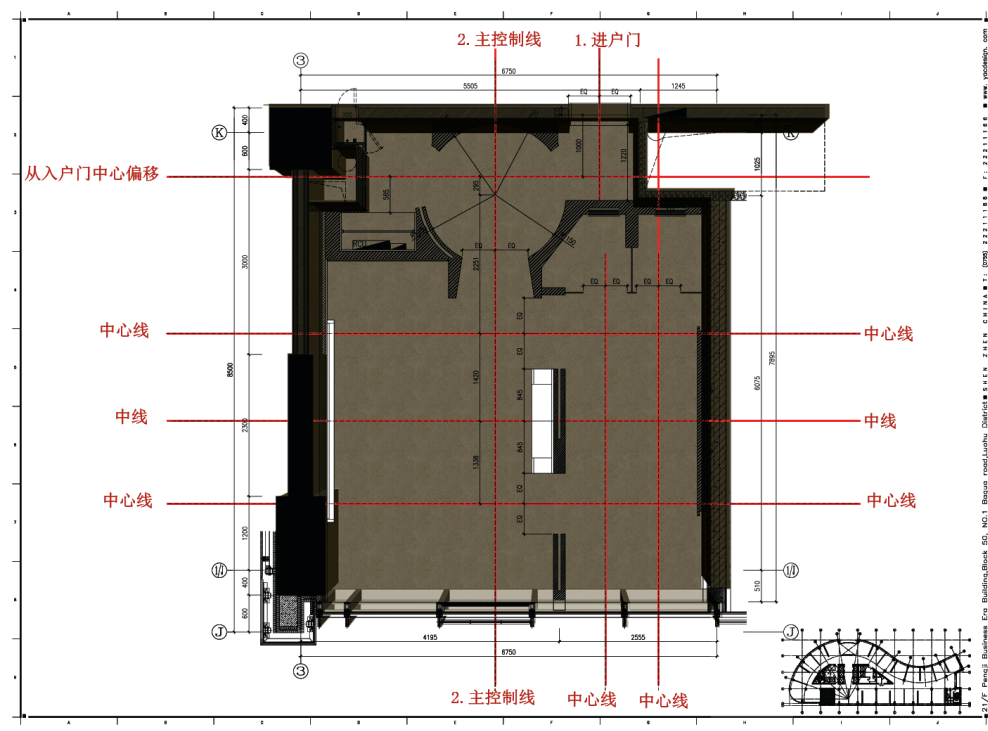

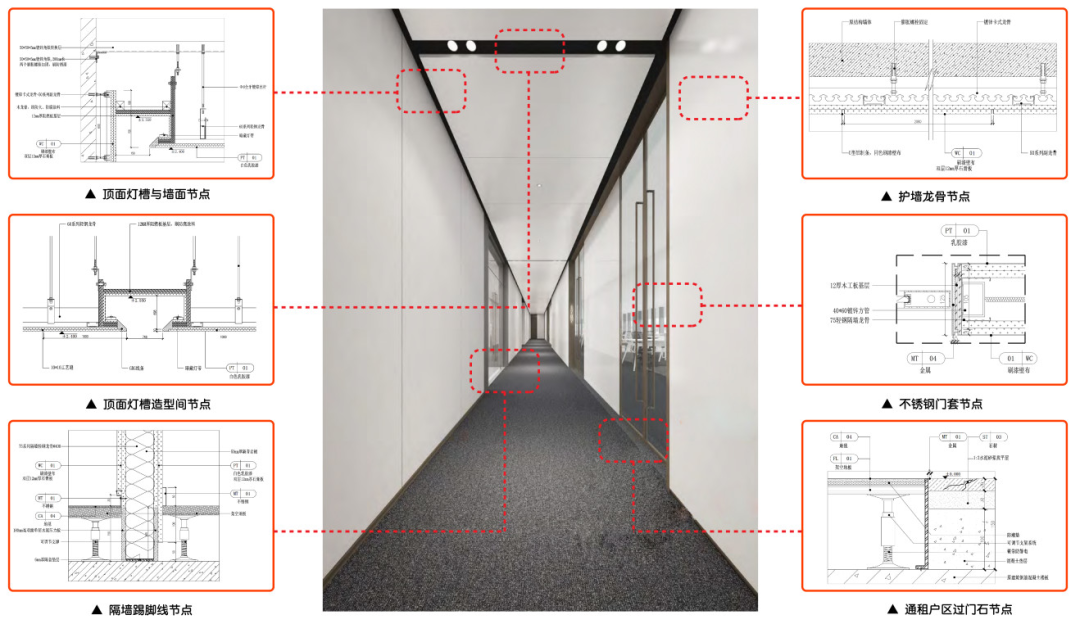

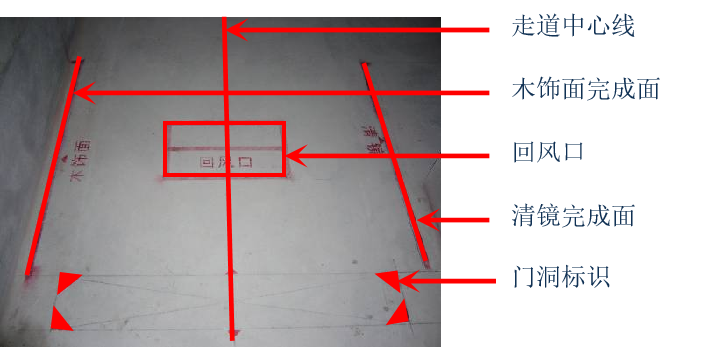

2.2.3 Line control

1, the main control line

2, the site to complete the face line

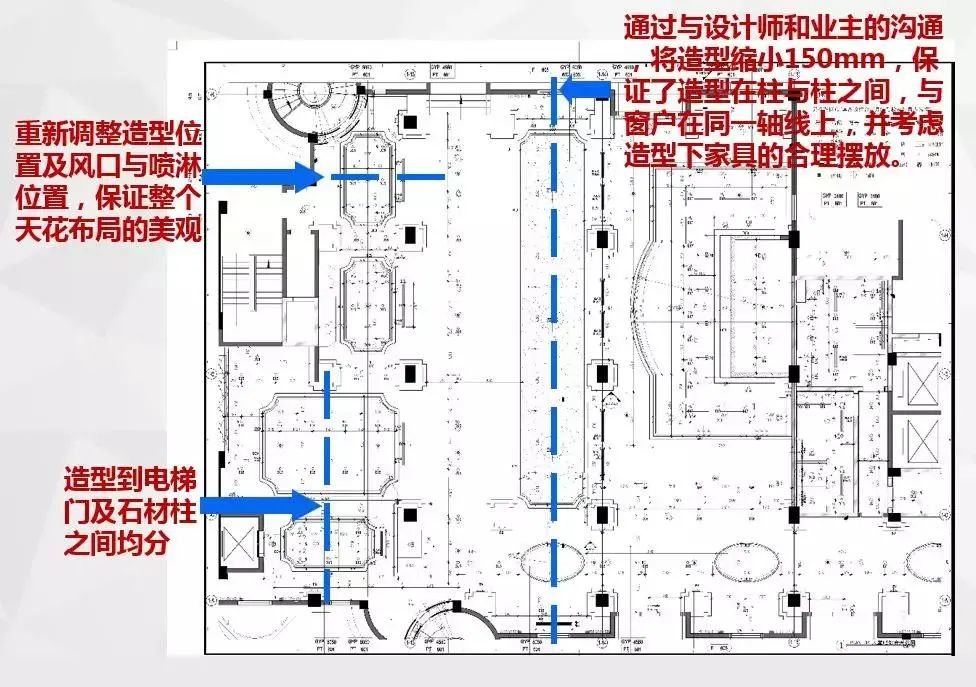

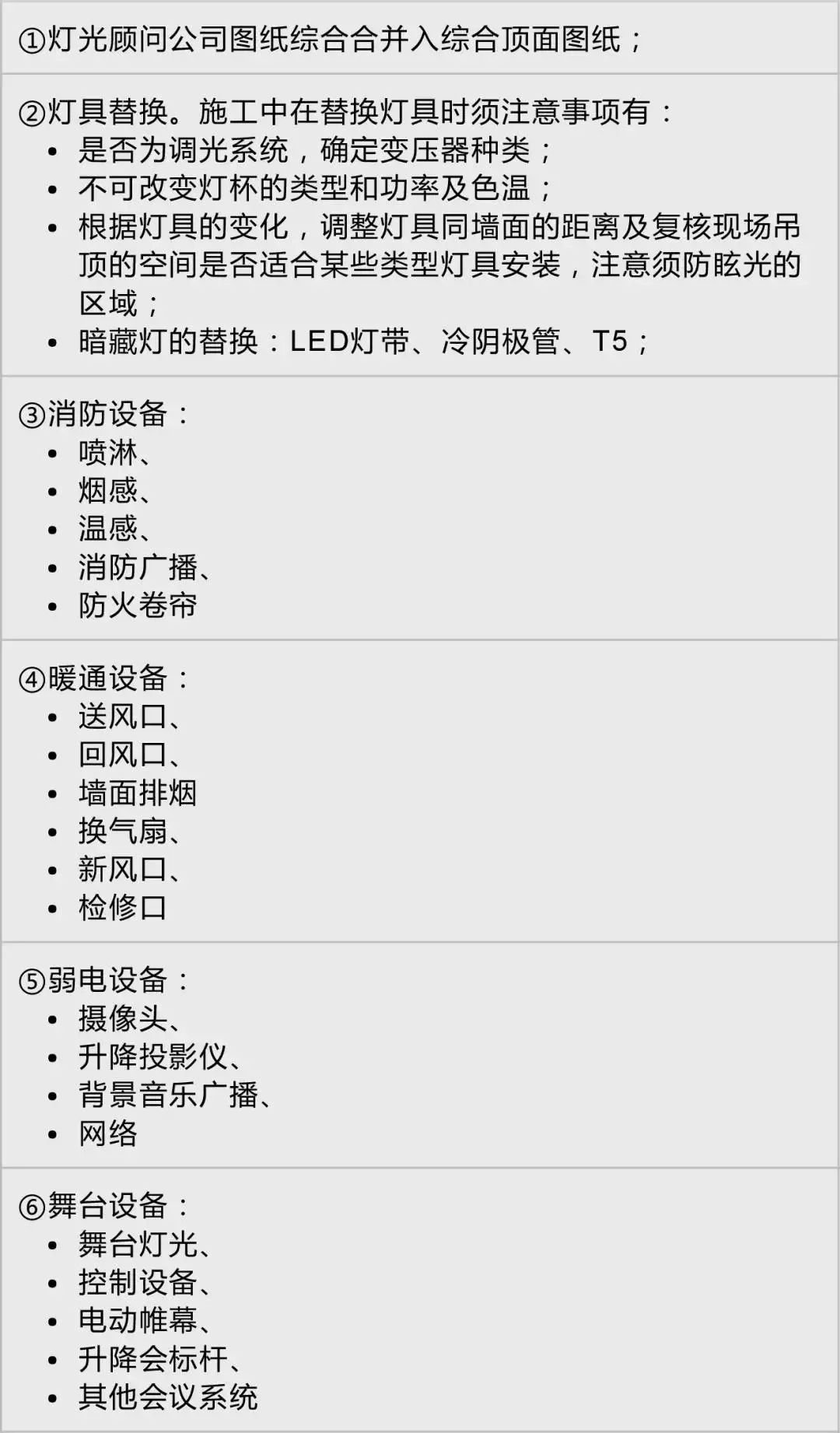

2.2.4 Comprehensive cloth point drawing

1, comprehensive floor plan drawing

Comprehensive point placement not only requires that all professional equipment can not be missed, to have the professional specification knowledge but also pay special attention to the relationship between the professional points.

Require points in the case of meeting the specification as beautiful as possible, horizontal vertical on a straight line, in a space around the point as symmetrical, balanced, and so on. A single point is as symmetrical as possible in the shape or symmetrical with the relative shape, etc. under the premise of meeting the specification.

2, comprehensive top surface drawing

Determine the ceiling height and material

Lighting fixtures

3, the ground and wall integrated cloth points need to pay attention to

The line is the whole project into the specific implementation phase of the initial link, but also the core basic link, is the entire project construction site review, but also the control of the closing between the materials, to ensure that the material joint order, to ensure the accuracy of the backfield material processing, to avoid the project late rush.

The quality of the line is related to the ability to achieve the quality objectives set by the project, for the construction workers, the line should adhere to the end, pay attention to the closing principle, after analysis and summary of the complex line release process through 16 to complete.

2.3

16 line ideas

01 Full partition reading | 02 Business planning program |

03 Put the line technology to the bottom | 04 Decorative axis deepening |

05 Place the decorative axis | 06 Measure civil construction deviations

|

07 Construction node deepening | 08 Drawing Cross layout |

09 Endpoint typography | 10 Drawings review signatures |

11 Complete the hatch drawing | 12 Place the finished face |

13 End forced positioning |

14 On-site on-site acceptance

|

15 The drawings are signed by all | 16 Materials jointly placing an order |

The decorative axis deepens

Measurement deviation

Plane complete face chart, data comprehensive axis measurement

Construction node optimization

Endpoint typography . .

Put the finished face line

The end forces the positioning of the

Jointly placing an order

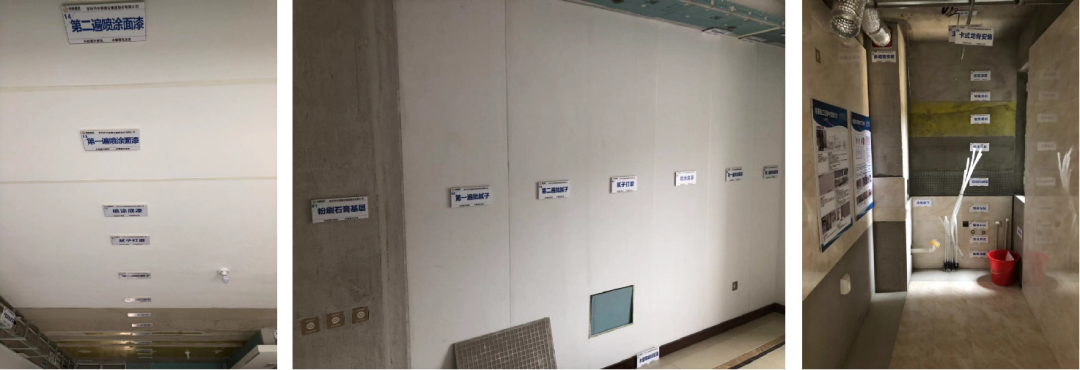

With the implementation of the “model first” system, the site problems will be exposed promptly, for the later construction to provide a basis, but also better control of the site

2.4

The model comes first

Enterprises can pass three models first, put an end to customer litigation risk, improve the satisfaction of owners. In general, the model includes the following first during construction.

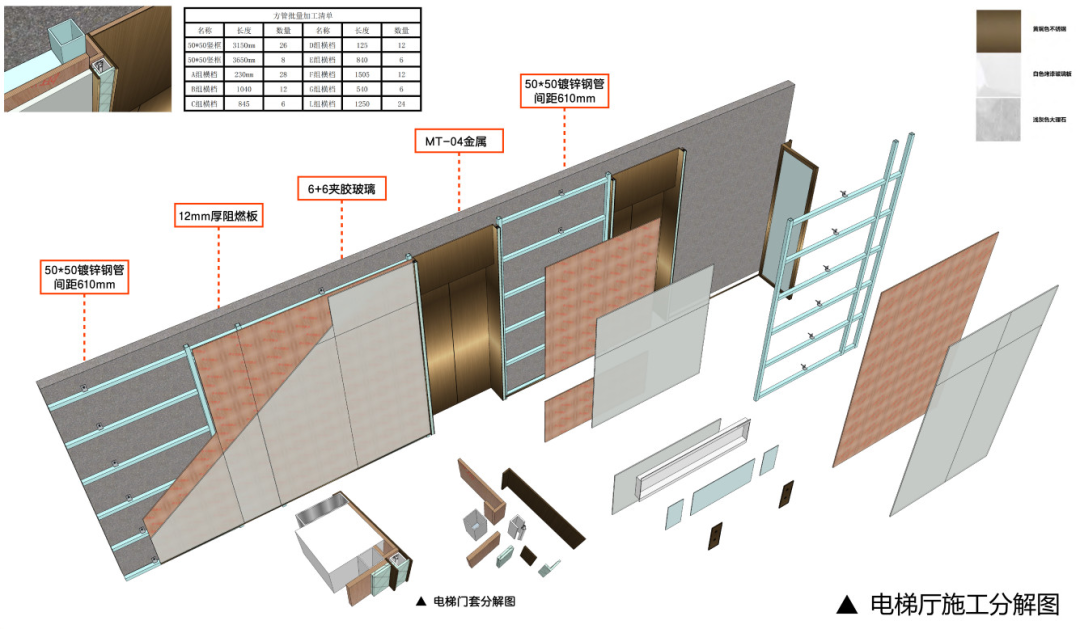

Solid model: By presenting the solid model and jointly reviewed by the responsible parties of design, procurement, cost, engineering, and construction, the unreasonable or wrong places are optimized and corrected, and the standards of product output are guided.

The process method model: unified construction quality standards, requiring each construction team to carry out construction according to this standard.

Paint the gypsum process / measured amount

Smallpox keel process/window sill stone process/window sill stone closing process

Ceiling latex lacquer process/wall latex paint process/wall brick process

Material model: clear material allocation standards, the formation of design seal samples, guide the bulk construction material standards.

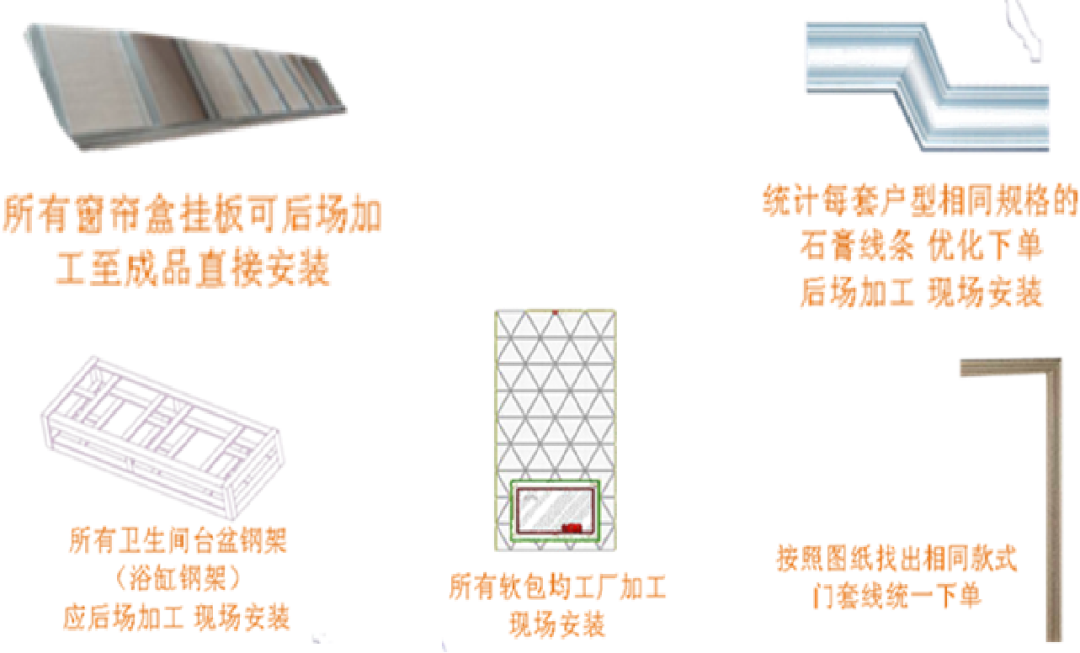

With the continuous development of productized decoration, modularization is gradually popular, ordinary on-site production has been unable to meet the pace of decoration today, to speed up the pace of construction, improve construction quality and reduce construction costs, semi-finished products on-site processing is the trend.

2.5

Semi-finished construction

1, semi-finished processing area main processing catalog

2, grass-roots semi-finished production

According to the smallpox keel layout and processing size list, to achieve in the semi-finished processing area processing ruler hanging board to the site assembly.

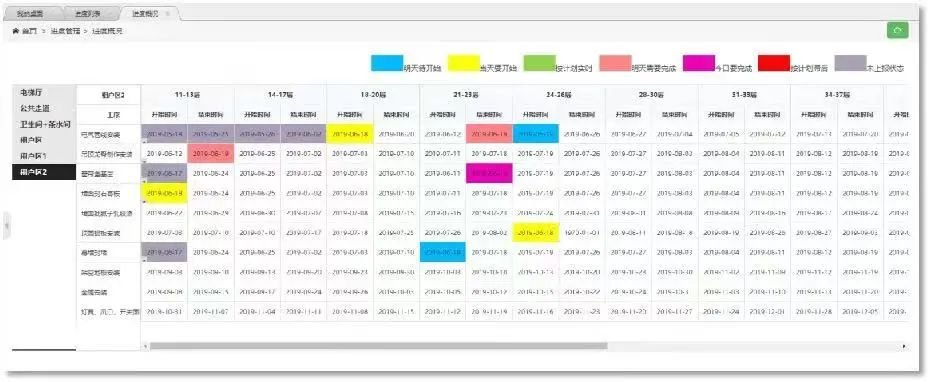

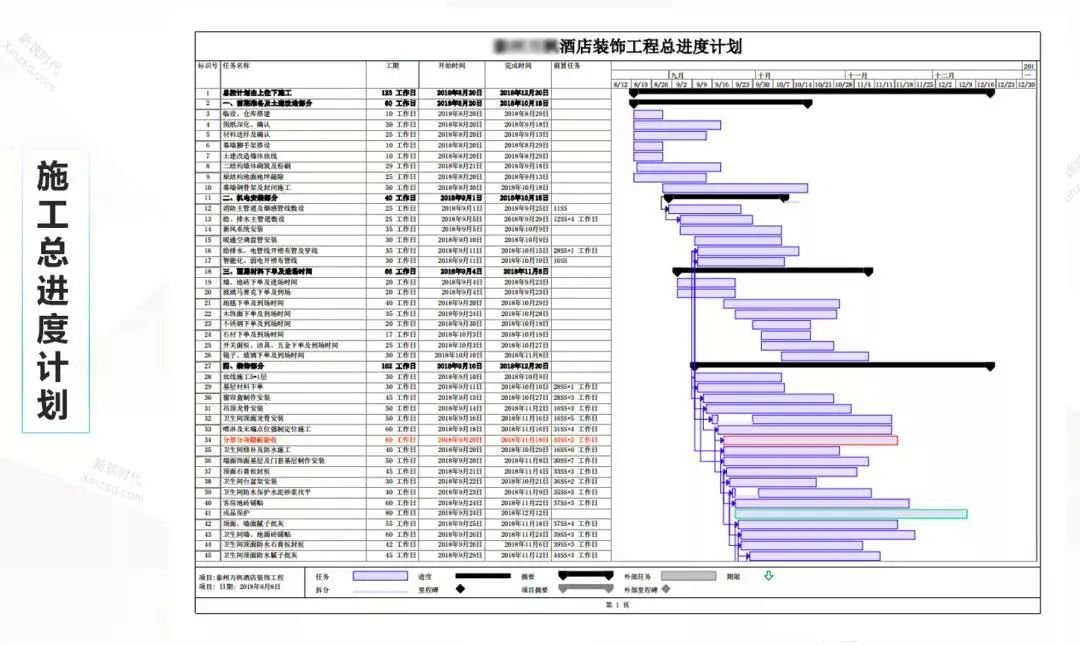

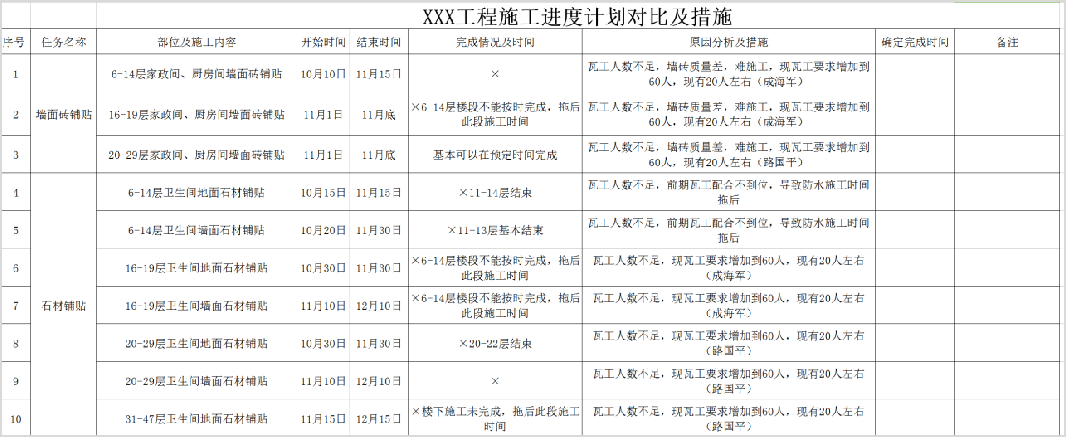

For the focus will affect the operation plan of the construction as the focus of attention, the key line process time directly affects the project duration, so in the early stage combing out the relationship between the key lines and parallel lines, is conducive to a certain duration, cost, resources under the timely adjustment of the arrangement of the best schedule.

2.6

Progress management

1, the key line map

2, key node schedule

3, the total schedule

4, progress correction

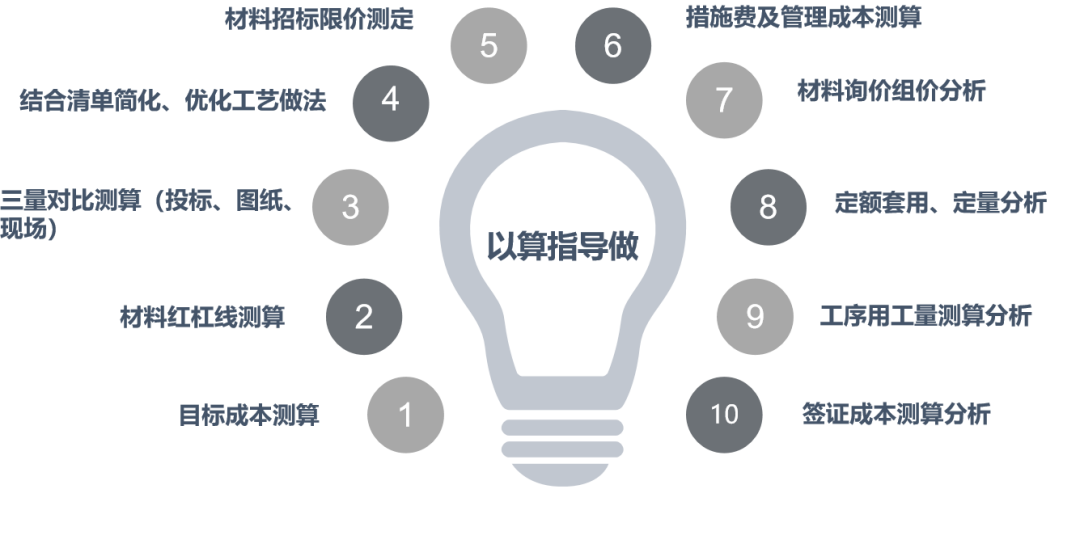

How to prevent project losses and expand profitability is a topic of great concern to all project managers, even project managers, and other company leaders.

In the actual construction process, focus on the “work, materials, fees” three blocks, respectively, cost control, to achieve the “turn a profit” effect.

2.7

Cost budget management

How to do it effectively in the construction process of the project “ to calculate the guidance to do it”?

03

The face layer installation phase

Processes that have special requirements or have a greater impact on the next process, or that are more difficult to process, have more quality fluctuations, or have more quality problems, should be controlled with emphasis.

3.1

Key operations are controlled

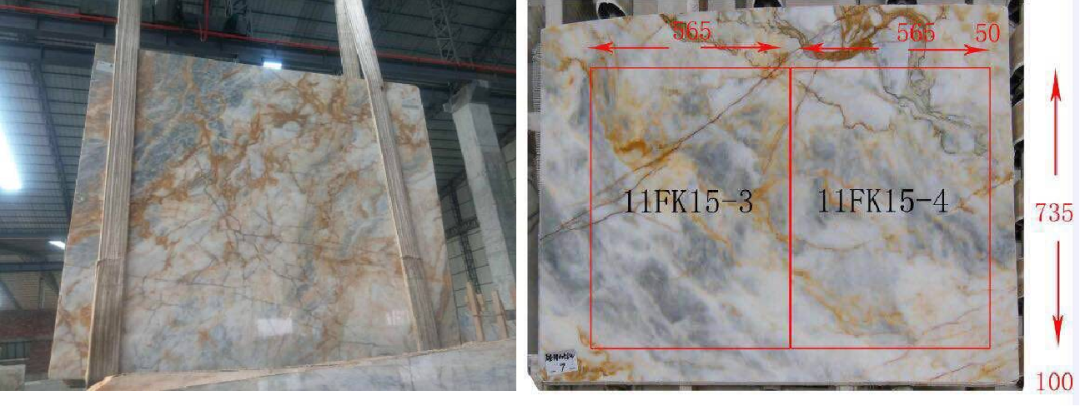

Take stone control as an example

Waste planning: because of the large difference in stone patterns, according to the amount of stone in each area, to plan stone waste;

1:1 Take a picture: each large board to choose the location to use;

Guide CAD drawings, according to the material photos for specifications layout;

Specification typography by materialized photo;

After the installation is completed, according to the color layout for on-site acceptance;

Almost 60% of the projects have the phenomenon of rush work, large volume, tight schedule, workers are not enough, temporary scheduling must rob! The formulation of the work-snatching scheme must be an effective process of “squeezing time, freeing up space and spelling speed”.

3.2

A job-snatching scheme

Identify key lines, deploy resources, favorable coordination of Party A, supervision, cooperation units, and other peripheral relations;

Horizontal segmentation, subregional rush;

A clear division of labor, the regional division of management, responsible for the person;

To clarify the completion time of key nodes, award and penalty points clearly, improve the execution;

Wood finishes and stone should be manned to prevent accidents in the middle.

To achieve the “perfect” effect, the project construction needs to control too many factors, from the project start, intermediate process, until the completion of the final stage, including the line, bottom, process supervision, management experience, and team construction quality requirements awareness, need to be managed, supervision in place.

3.3

quality control

1, process nodes, quality disease, effect map on the wall

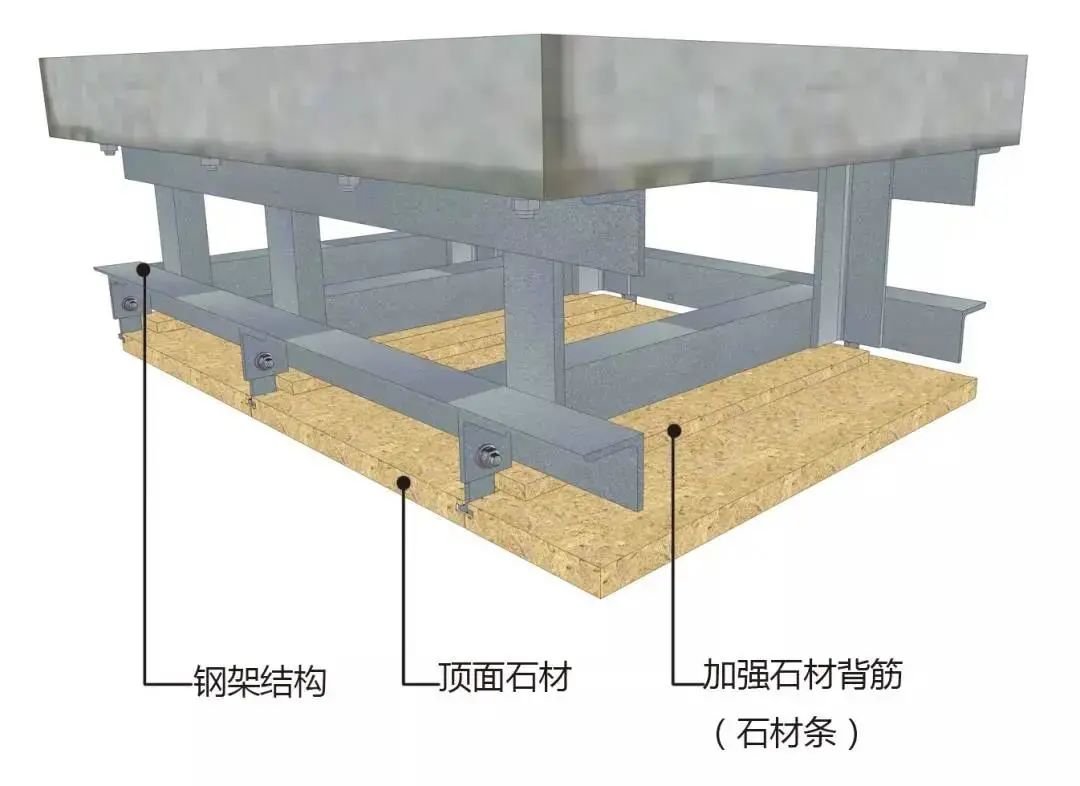

Case 1: Top anti-hanging stone does not meet the relevant standards

Pre-control of general disease:

(1) The pre-design consideration of the use of imitation stone material for local replacement, or layout size should not be too large.

(2) When the top marble is dry hanging, the dry hanging point and seam position should be reinforced twice to increase the back strip.

(3) Paste with AB glue, do not use cloud stone glue.

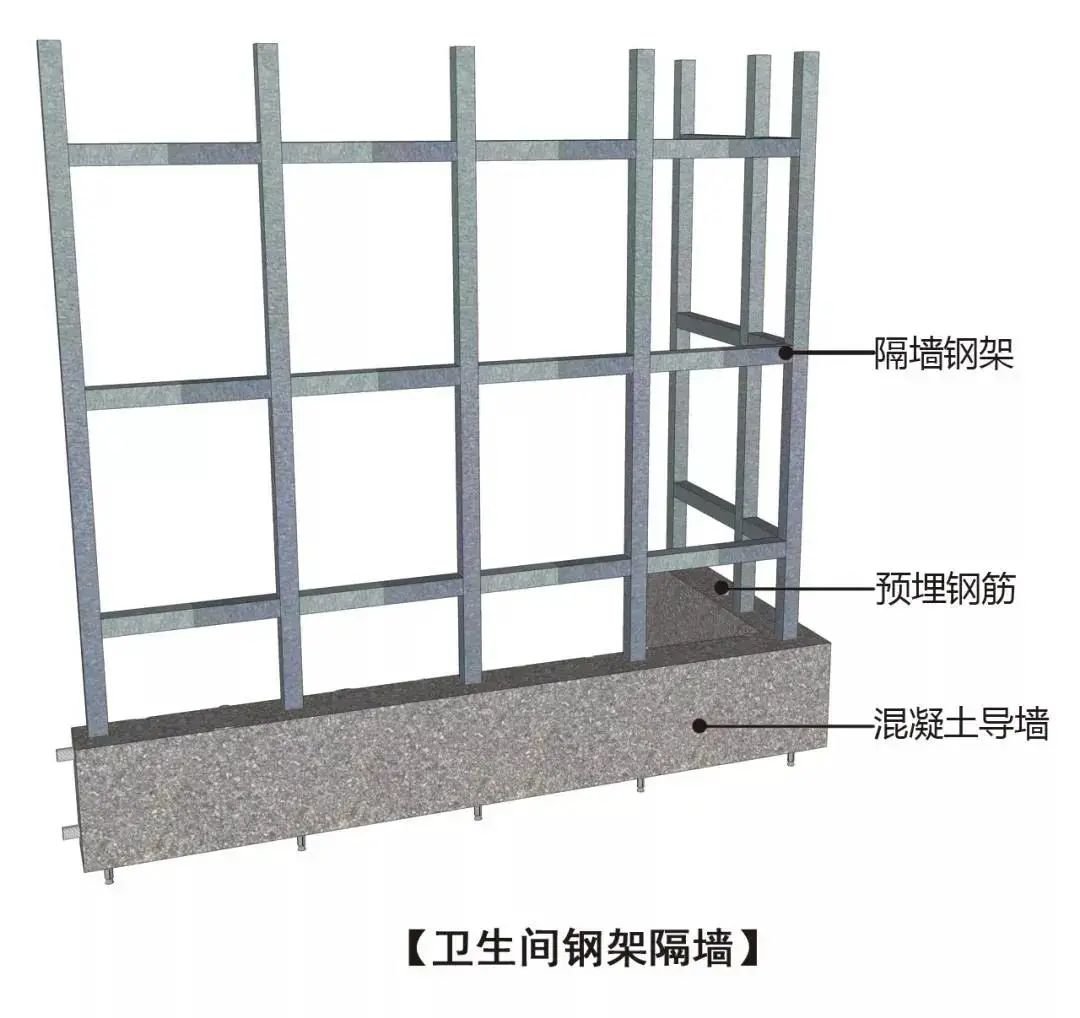

Case two: bathroom steel frame directly landing, do not do ground beams

Pre-control of general disease:

(1) clear requirements kitchen or bathroom and other areas with clear waterproof requirements to do guide beams, do a good job of the team’s construction process.

(2) Familiarize yourself with drawings and focus on areas with waterproofing requirements.

(3) Concrete guide wall with waterproof function requirements, recommended to 200mm high.

2, productized construction process arrangements and delivery bottom

Division of the zoning flow section;

The installation and construction process arrangement from the release line to the surface material;

Standardized size control of the line, easy to standardize the deep-processed materials;

Supplier production delivery sequence planning arrangements;

Project members, cooperation units, and supply chain to carry out the bottom.

What is the process like under product-based decoration? How is it different from traditional decorative process practices?

What can you tell you in the project Manager with20 years of experience that is the correct workflow for “productized decoration”? This article learns the workflow of productized decoration.

3, technical bottom

Technical bottoming is an extremely important technical management work of construction enterprises, is the continuation and improvement of construction programs, but also the last pass of project quality pre-control.

Bathroom basin cabinet installation of the bottom

(1) The back of the basin installation uses a hanging horse strip.

(2) Installation must be installed, specially opened, the opening must be using special opening equipment, the opening must be processed in the factory to the site.

(3) The plumber must be notified before installation to check that the water pipe on the wall meets the requirements.

The door cover and door fan mounting cross-bottom

Door cover grass should do impermeable treatment, the stone door can be extended into the door cover, to prevent mold.

Wipe the seams, make the seams and cross the bottom

(1) the ground crevices using resin glue plus cloud stone glue tint for filling treatment (two fillings, after the seam should be 1mmhigher than the stone surface);

(2) The ground stone should be dry after laying in the seam.

3.4

Finished product protection

Set up a special packaging group, organize visits and training, do a good job before packing, different methods of different components (ware, etc.), strengthen safety education, increase inspection efforts, maintain packaged finished products, dynamic zoning, responsibility to people, strengthen the protection of corners, which is the most vulnerable place in the face, strengthen the security of small valuables, pay attention to human safety, at this time can not be paralyzed, more can not be a safety accident.

Hardware protection: Wrap with original packaging materials

Switch panel protection: Wrap with original package material

04

The closing phase of the project

4.1

The elimination plan

Quite like this table, since there is a schedule, there must be a sales table, daily update records, not finished into a timely collation of the notification, the next day the project department to take appropriate measures, to ensure that the time to recover.

4.2

Details corrected

Stone yang angle detail correction by the manufacturer specially polished 3mm bevel angle

Earless door cover grooves and correction with wall brick closing details:

The door cover and the wall brick gap are treated with porcelain white glue

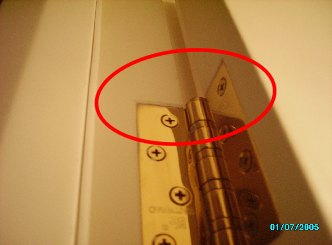

Door-to-page correction details:

Screw carpentry adjusts the cross, the door frame, and the joint sheet repair flat

4.4

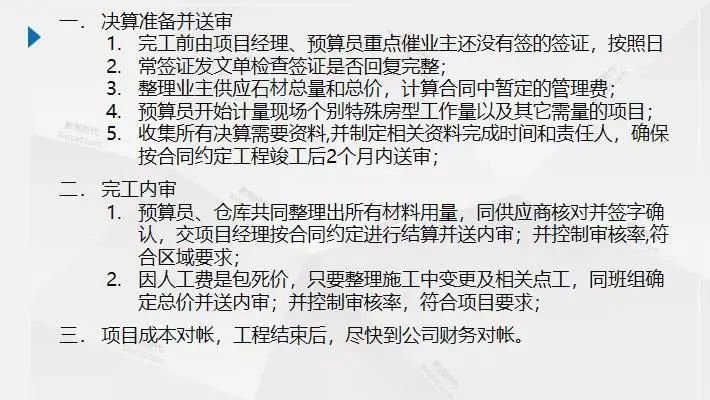

The final accounts are sent for trial

Project management is a complex and systematic project, with good ideas, good methods, good tools, but also needs strong implementation, only to complete a satisfactory work, the real implementation of the customer-centered concept.