The golden age of assembly decoration is coming, are you ready?

01/ What is an assembly decoration

Assembly decoration is like building LEGO bricks. The whole house decoration materials, divided into a standardized module, units, components, a piece of land combination, you can build a completed space, and traditional decoration may be to make their own each block of building blocks to start.

The standard interpretation of industry norms: assembly decoration, refers to the use of the dry-type method, the factory production of materials in the decoration site for the combination of installation of the decoration method.

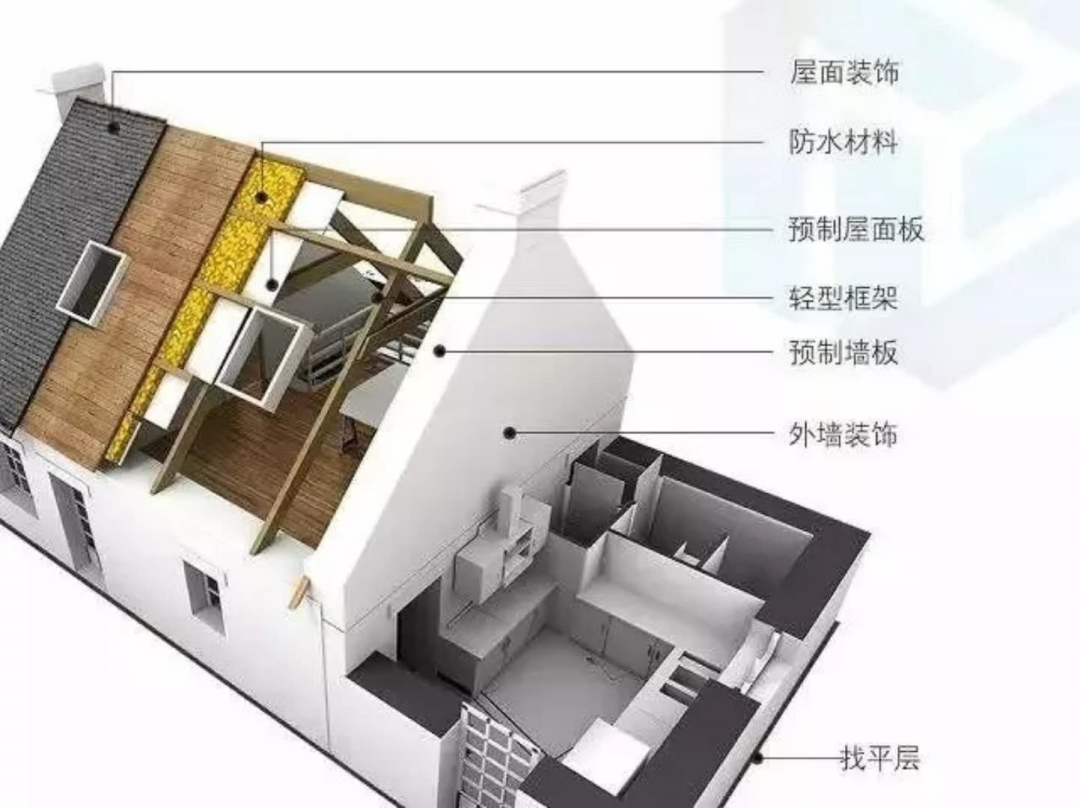

A diagram summarizes the assembly decoration

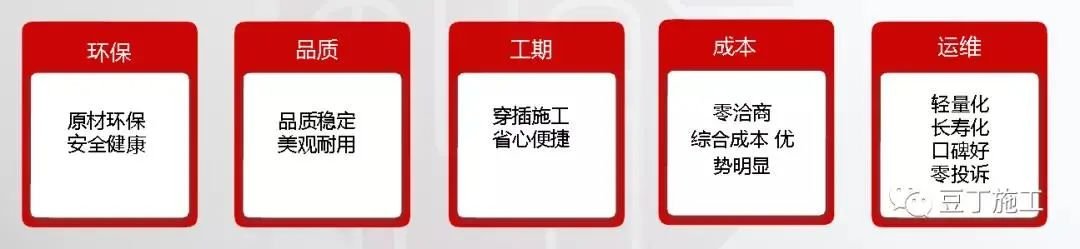

02/ Application advantages of assembly decoration

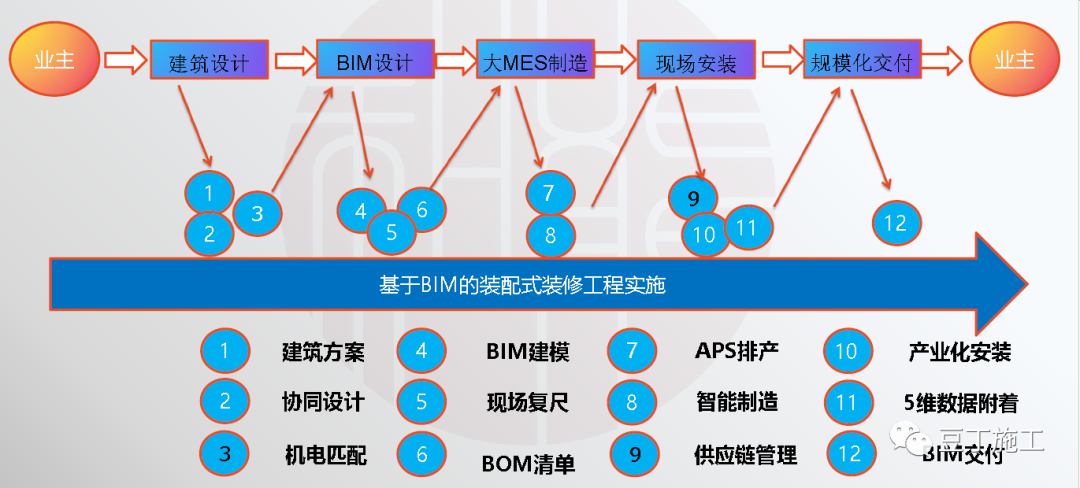

03/ Assembly decoration process

04/ Assembly decoration technical basis

The three technical bases of assembly decoration are SI separation technology, dry construction technology, and site assembly construction technology.

1, SI separation technology, that is, the building’s load-bearing structure skeleton (Skeleton) and internal space (Infill) separate, the structure of the building is immutable, after measurement, the internal space design is variable, by the building user to decide;

2, BIM technology, that is, building information management technology refers to the system input household type and other data, digital information simulation of the building has real information, and through the three-dimensional building model, to achieve engineering supervision, property management, and other functions;

3, construction assembly, refers to the production of parts in the factory, to the construction site to assemble mainly, only simple tools and steps can be completed, site construction almost zero cutting.

05/ Features of the assembly decoration project

1, integrated design: the best design combination point for the architectural design phase of the integrated design, is conducive to cost optimization, configuration optimization, avoid duplication and waste. For many projects to enter the decoration construction before the start of assembly-style decoration program, engineering design, the determination of the engineering interface directly affects the design quality, product manufacturing, engineering preparation, process handover, smooth engineering procedures, and so on.

2, engineering organization: from the integrated design of the organization and management to the site of the standard segment division, to the transfer of the construction surface, to the transfer of the process, assembly-style decoration features are distinct, the need for the owner’s design and management norms, the general contractor’s engineering organization, and management more standardized and procedural. Assembly decoration is more sensitive to the irregularity of the order of on-site engineering organizations and needs the construction unit and general contractor to continue to deepen their understanding of assembly decoration or construction industrialization.

3, process handover and cross: unlike the traditional model, assembly decoration process handover needs construction surface system handover. In terms of cross-operation, the failure of the previous operation has a great impact on assembly decoration.

4, the importance of line measurement is very prominent.

5. The industrialization of the labor force is much more important than the traditional construction mode.

6, supply chain management thinking: Unlike the traditional material management thinking, which takes centralized procurement as the main way, supply chain management is to link the production enterprises to the value chain, information chain, and logistics chain to complete the project together, which plays decisive support for the effective response, the optimization of value and the realization of data coherence

7, node practices and expression: involved in research and development than traditional decoration, and more need manufacturing support;

8, project acceptance: At present, acceptance procedures and basis and traditional decoration are no different.

06/ China’s assembly decoration development status

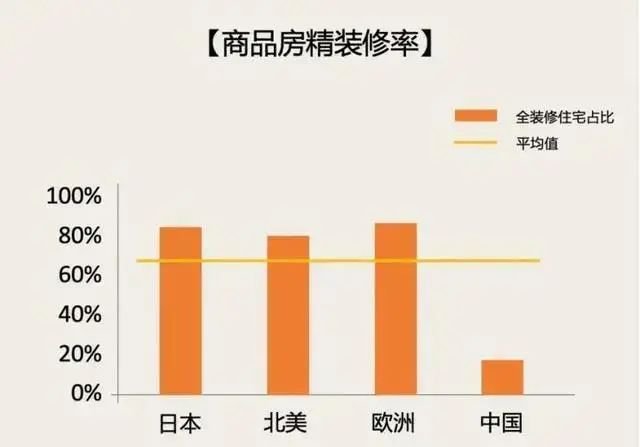

At present, China’s assembly decoration development level is low, a large number of delivered housing in the form of rough or semi-finished housing, the proportion of fully renovated housing is about 20%, far lower than Japan, the United States, and other countries 80% of the level, limiting the use of assembly decoration.

China’s full decoration development started late, the proportion of fully renovated housing is much lower than developed countries

(Source: Network Disclosure Data)

07/ Sharing of typical problems in assembly decoration works

1, design management caused by engineering problems

A project, on a large scale. Due to its large size and a small number of households(4 households), the design is assigned to 4 design units.

Problems:

1, in the different design section of the same household type, because of different design unit design, mechanical and electrical point location difference is large, and the design does not have unified control unit management, resulting in assembly-style decoration to deepen the implementation of the design is difficult, the next process complex through high.

2, arbitrary changes lead to uncontrollable costs. Due to the construction unit’s lack of clarity on the model pattern, changes occurred after the construction of the project, resulting in the scrapping of some processing department products, the increase in engineering costs exceeded the construction unit’s expectations.

suggestion:

1, integrated design is still the key to solving the design problem.

2, assembly decoration design control of the importance of construction units need to attach great importance to.

3, model guide, the model pattern must be resolutely implemented.

4, give the design enough time so that the design is mature, stable is the construction unit, the general contractor necessary cognition.

2, engineering interface management caused by engineering problems

In a project, the general contractor controls the time with the traditional decoration subcontracting thinking, to ensure the progress of the project, the wrong division of the project interface leads to a large number of problems in the progress and quality of the project.

Key issues:

1, the grass-roots keel from the total package is divided into traditional process construction, a surface installation by the assembly-type decoration process to complete. Because the traditional process keel installation can not match the assembly decoration error system, resulting in the keel leveling time being extended, and the quality can not be guaranteed.

2, following the traditional decoration thinking requirements of the assembly-style decoration process, resulting in slow progress and quality problems a large number of appearance.

3, ground-based leveling for the traditional process of construction, ground surface layer and wall surface layer for assembly-type, kicking line under the mouth and ground junction of the gap size uneven, wave-shaped gap and other issues affect the quality of perception acceptance.

suggestion:

1, error system matching determines the division of operations, not arbitrarily.

2. The general contractor must have a deep understanding of assembly decoration or building industrialization and understand the obvious difference between the construction path and the general way after industrialization.

3, the delivery of the building as a complete product to treat. 4. The technical cycle of assembly decoration and the organization of different processes, cycle compressibility, and so on need in-depth understanding.

3, cross-management caused by engineering problems

A project, the general contractor to recover the delayed progress, requiring assembly-style decoration process forced entry into the construction, resulting in a large number of progress and finished product protection problems.

Key issues:

1, the work surface (delivery space) is incomplete, resulting in the field measurement line operation can not being implemented.

2, civil construction process and assembly decoration process parallel, seriously affecting the assembly decoration flow process and rhythm, resulting in slow progress.

3, unreasonable and inverted logic of the operation cross led to a large number of finished product damage, seriously affecting the progress.

suggestion:

1, assembly decoration or building industrialization of the process has a completely different logic, need to take seriously, careful organization, especially the project progress management needs comprehensive planning, can not be over and casual.

2. The general contractor must have a deep understanding of assembly decoration or building industrialization and understand that the construction path after industrialization is different from the traditional way.

3, will build all processes a complete product manufacturing chain to treat.

08/ Assembly vs. traditional decoration

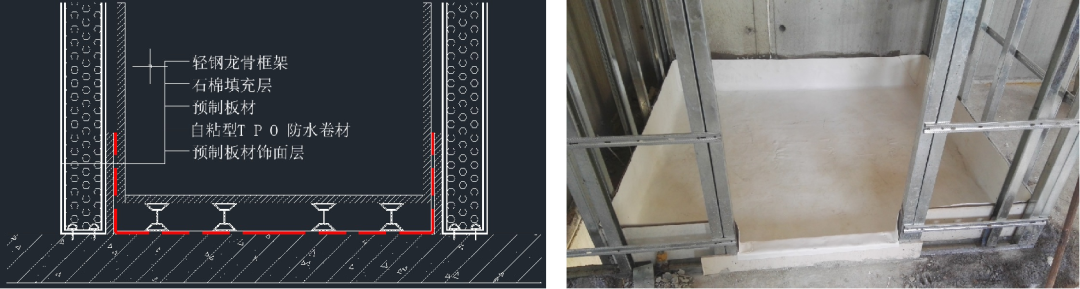

We use the waterproof construction of an assembly building as an example:

1, the traditional building bathroom waterproof structure

Wall ground line pipe more, bathroom space area is small and more cross-section.

shortcoming:

(1) The use of molded coil paving construction will result in tube roots and other details of the sealing are not strict and indoor environmental protection requirements and other factors.

(2) The use of waterproof paint for construction, the existence of the coating film drying time by the impact of the environment, and coating thickness need several times to form.

(3) The thickness of the coating film is greatly affected by the operation of the construction workers, and the overall thin thickness of the coating film is uneven, seriously affecting the quality of waterproofing.

2, assembly building bathroom waterproof structure

The waterproof construction base of the assembly residential building has no pipeline arrangement and no more cross-sections.

shortcoming:

(1) The use of paint construction, is wet work, construction duration is long, efficiency under (waterproof to complete the closed water takes about 7 days).

(2) The film thickness of the coating is difficult to control (the grass-roots and construction methods determine the quality of the coating film).

(3) The film is low and soft, and the upper part is easily damaged when there is no protective layer (cannot be stepped on directly).

(4) Existing polymer modified asphalt or acrylic coils will have open flame construction and wet operation, and will not be environmentally friendly.

3, TPO coils in the assembly toilet application

The assembly building toilet uses self-adhesive TPO coils with pressure-sensitive adhesive on the surface for waterproofing of the flat façade. The connection between the coil and the coil is done by welding with a welding gun.

TPO waterproof coils combine the performance benefits of EPDM and PVC with weather resistance, low gentleness, and weldability of the latter, while TPO waterproof coils are highly flexible without plasticizers. Plasticizer migration, such as PVC, does not cause premature aging, cracking, or coil shrinkage of coils, and has the characteristics of high strength, high puncture resistance, high tear strength, and minimal shrinkage.

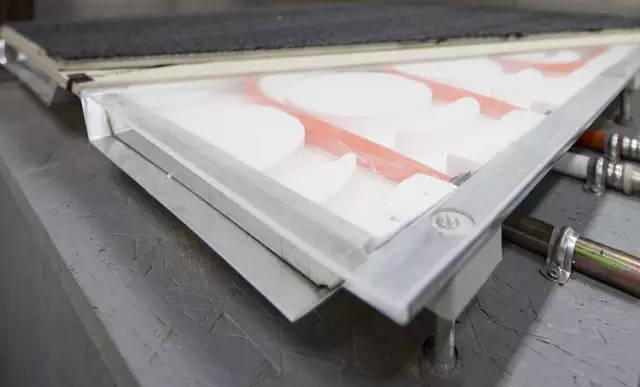

Examples of ground systems:

1, system construction

(1) Overhead feet support custom modules, overhead layer arrangement of plumbing pipes.

(2) Level the ground foot bolts and have strong adaptability to 0to50mm floor deviations. (3) Heating Underfloor 20 years Quality assurance, flexible in-module insulation board cloth tube.

(4) Protection configuration removable high-density balance plate, durability.

(5) Floor ultra-wear-resistant integrated imitation wood-printed glue-free flooring, fast assembly.

2, system advantages

Significantly reduce floor load, the support structure is strong and durable and high flatness, protection layer balance plate thermal efficiency is high, on-site assembly efficiency 300% improved, operating environment friendly, pollution-free, garbage-free.

–END–