How about bulk hardcover repair? Look at the late-night summary of the front-line project manager, and you’re more confident about doing a good job

Deepen the design

2.1

Deepen the accounting

Hardcover project the main optimization area for the living room, bathroom and public area dark door closing node, such as project A party and the owner requires the node to be sent for confirmation, before large-scale construction, must sort out the optimization node list items.

Deepen the design ledger

2.2

Node deepening

According to the design of the bottom, drawing triage, put the line problem summary after deepening the construction drawing.

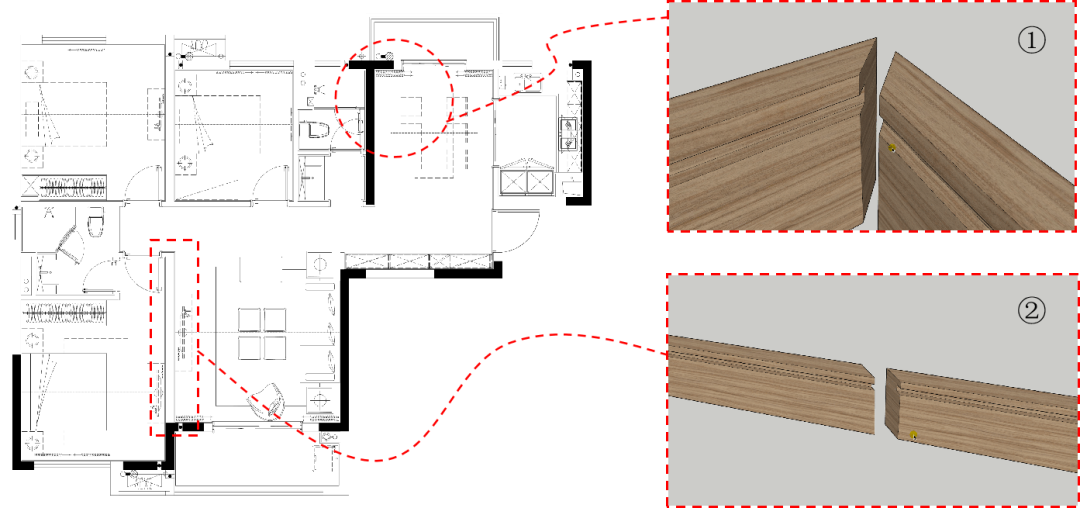

Kicking line:

Figure (1): The clitoris / yang angle of the wooden kick line is stitched 45 degrees to avoid gaps in the shape

Figure (2): The wooden kick line is stitched at 45 degrees to avoid problems such as excessive cracks and cracking

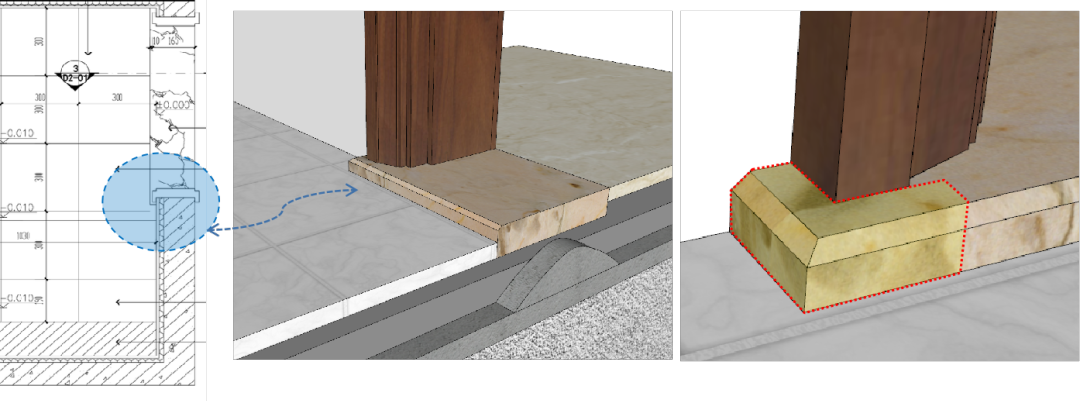

Threshold stone closing:

The door sleeve falls on the threshold stone to enhance the water resistance

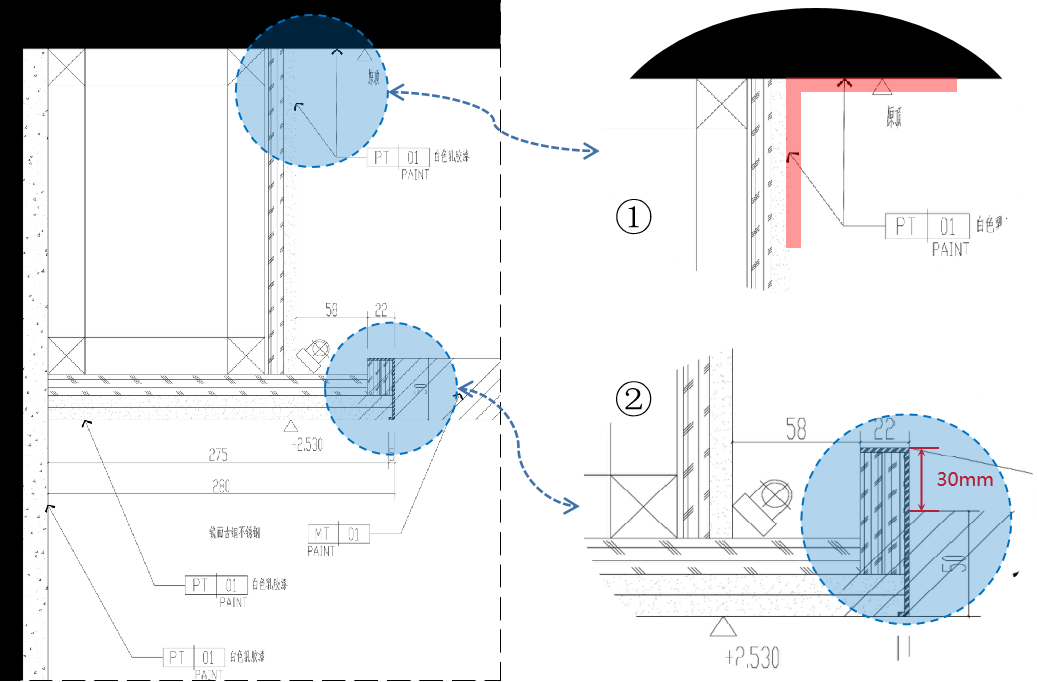

Light belt optimization:

The lamp slot is too low to see the lamp belt

Figure (1): The is reinforced with a bandage at the corner

Figure (2): The lamp groove deepens to prevent the sighting of the lamp belt

Window sill optimization:

Remove the bracket while extending the two sides by 1 centimeter, propulsion mounting

2.3

Typography deepens

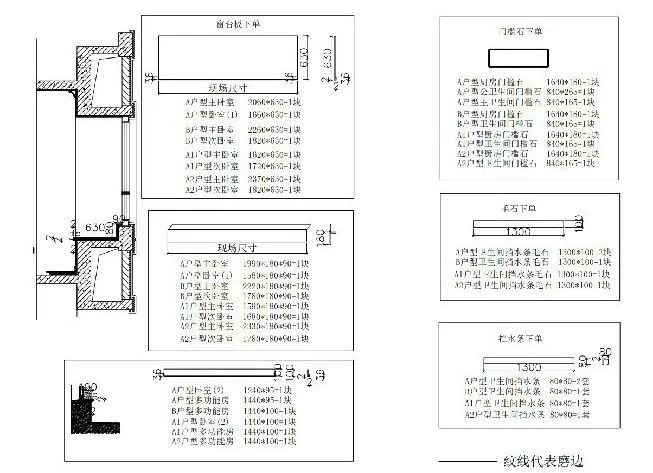

Stone typography: window sill board and threshold stone volume is relatively large, so the stone processing, productization after-field processing, entry plan requirements are greater, the project department reviews the stone manufacturers after deepening the drawings, the stone manufacturers put forward processing requirements, entry time;

Stone deepens typography

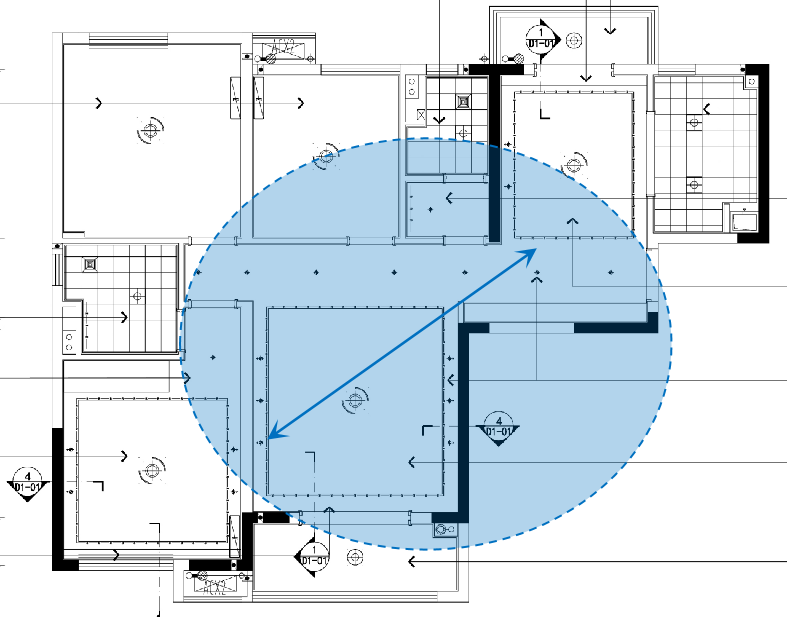

Tile deepening typography: Set the appropriate placement reference point according to the household design plan. (1) Set the main control line;(2) clear placement control Size;(3) Plan the placement order.

The order in which the living room floor is laid

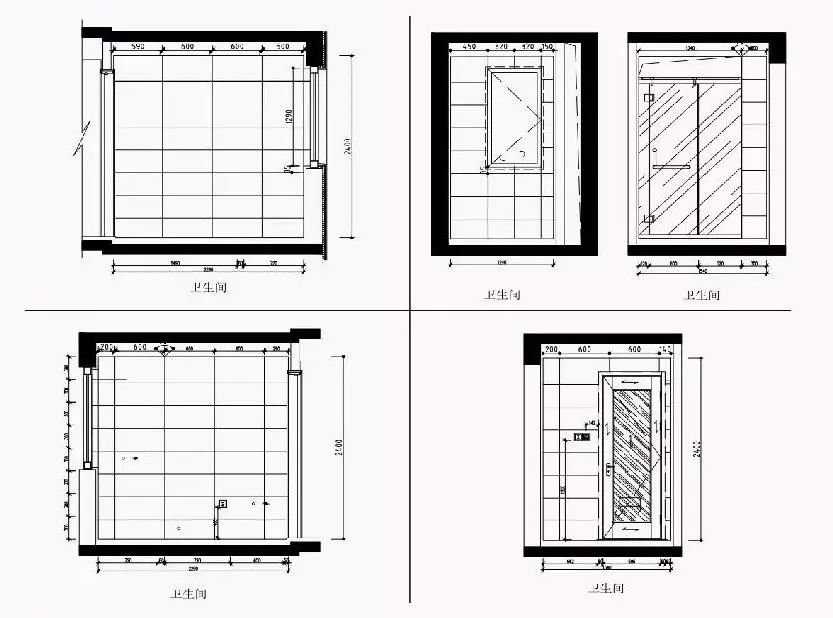

Bathroom wall layout

The tile deepens the typography under the single figure (example)

Window sill slabs, sill stones, etc. are single-figured

Through the actual measurement of the ground layout, the main control line of the floor tiles has reflected the site, for the tiles to lay ready, which includes the floor tile orders, cement mortar whether there is sufficient storage, the removal of ground ash.

Floor tile paving technology cross-bottomed

Check the quality of bricks: in the field to find an area test floor tiles, my department arranged for the team in this location to lay, will be norms, requirements, precautions one by one to the bottom.

Floor tile paving technology to the bottom

Wall tile patch (model display)

03

Product construction

3.1

Central processing

Site requirements: the site needs a hard site, all sites after site survey, the original site for the soil ground, hardcover units need to harden themselves, after withdrawal for demolition and clean-up, transfer of the occupied site downstream units.

Material types requirements: cutting welding, grass-roots, finish materials, installation of mechanical and electrical, mixing.

Process management requirements: To improve processing efficiency, the same specifications of materials centralized processing, but at the same time need to take into account the operating surface according to the needs of the set of construction. According to the batch size, the building can be divided into several batches, the same batch of the same specifications of batch production and processing.

Processing requirements:

Set up a centralized processing zone

3.2

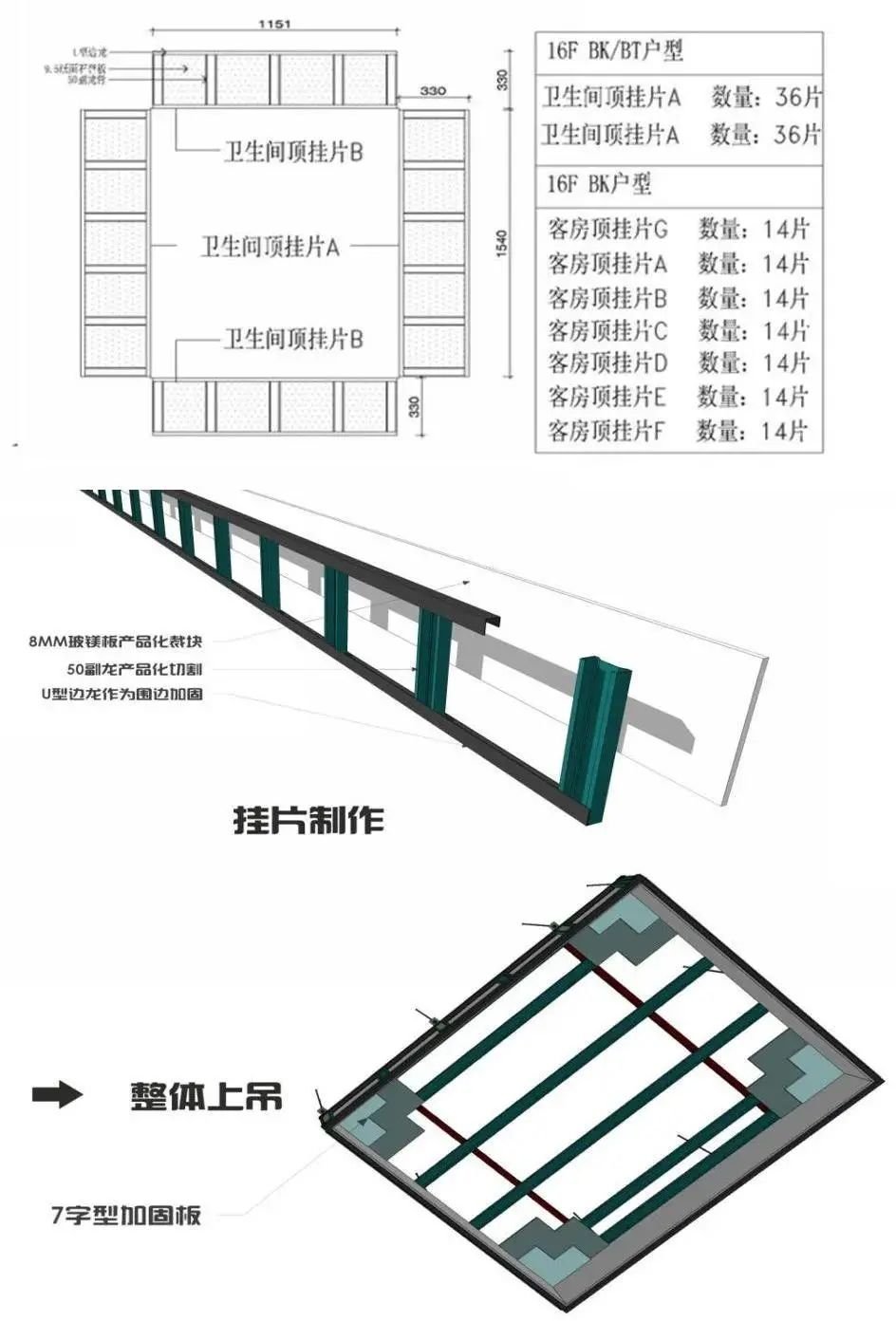

Modular processing

Management requirements: To speed up the construction speed, improve the quality of construction and reduce construction costs, the establishment of semi-finished products and finished off-site processing areas is the trend. “Products” that can be digitally molded, such as:

(1) ceiling wire rod, the back yard cut into standard length;

(2) Prefabricated keel can be cut and assembled in the backfield;

(3) Hanging board can be processed in the back yard, construction site installation;

(4) wooden doors and door covers can be unified size back yard processing production, on-site installation;

(5) Toilet hand-washing table and mirror cabinet can be the same size, on-site assembly;

(6) Bathroom batch partition uniform specifications, one order;

(7) Bathroom basin steel frame in the back yard for pre-assembled, welding molding;

(8) Tiles/stone and other surface layers can be unified size processing orders;

The upper split ceiling unit is finished under the order

The motion map shows the

04

The model comes first

4.1

The process is at the bottom

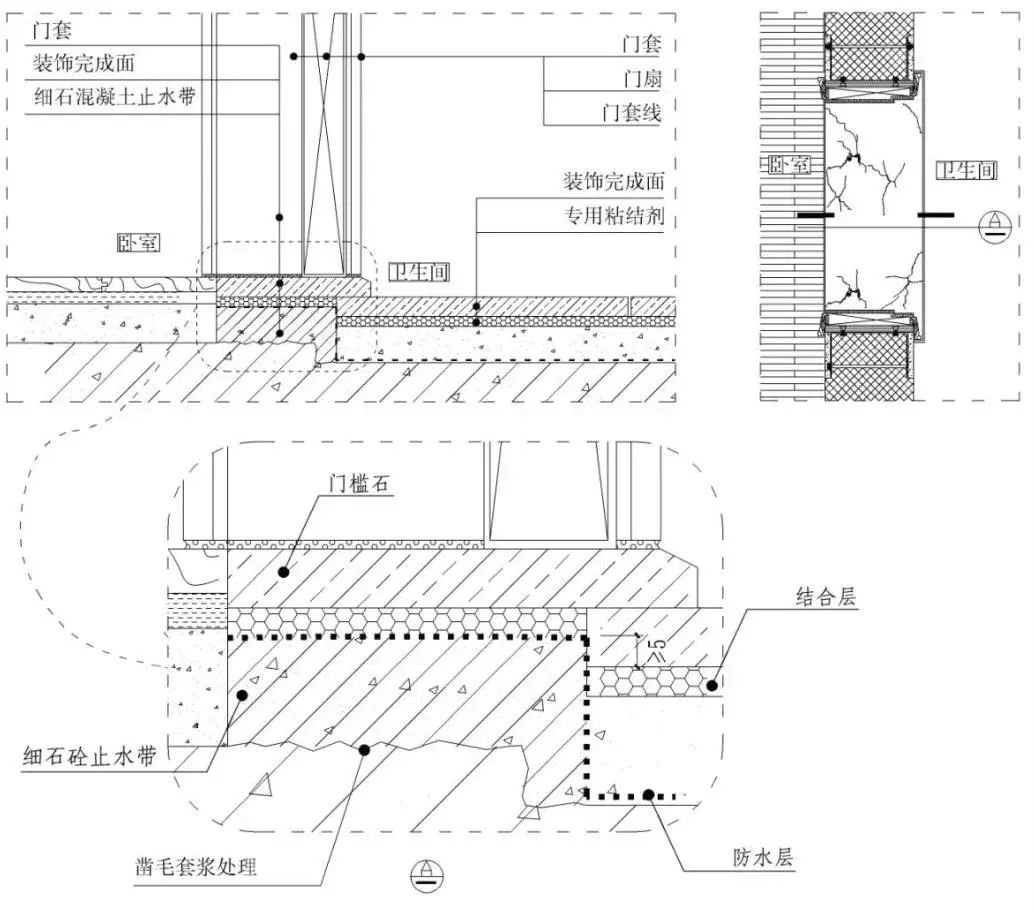

The toilet threshold stop water belt construction diagram:

Highlights:

(1) Bathroom (design has high difference requirements) threshold Stone base should be set up a water stop belt (first in the structure board wool cover pulp treatment, and then the use of fine stone pouring forming), and with the ground to do unified waterproof.

(2) The water-stopping belt should be higher than the waterproof area binding layer of more than 5mm.

(3) The wooden base of the door frame should be treated with three anti-corrosion (fire, corrosion, and moisture).

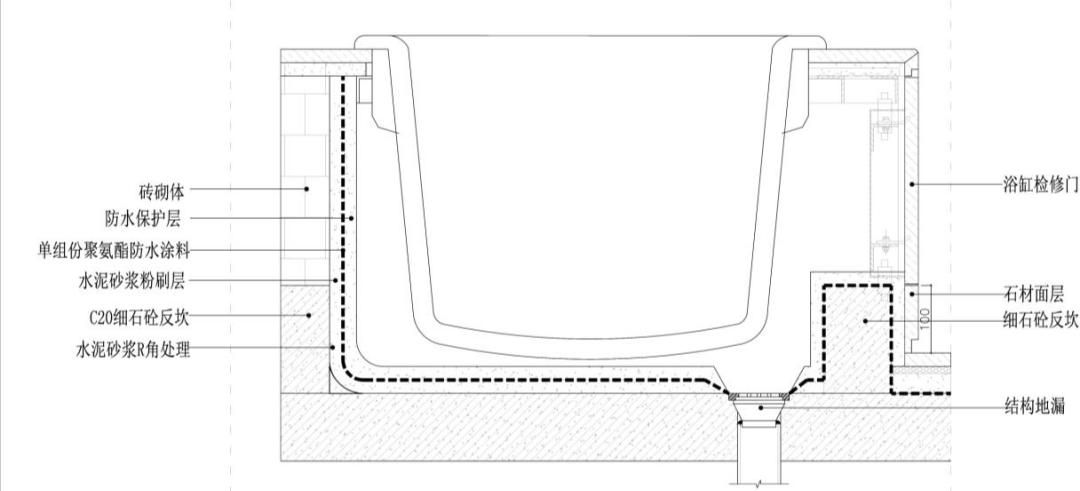

Bath waterproof node construction diagram:

Highlights:

(1) A structural leak should be added to the bottom of the bathtub to facilitate the discharge of standing water.

(2) ≥ C20 fine stone concrete back beam with a surface finish surface of 100mm should be set around the bottom of the bathtub. After the construction of a single component polyurethane should be erased 1: 2 cement mortar waterproof protective layer together. The side of the bathtub should be set up with access to the dark door.

Wall tile yin and yang angle closing diagram:

Highlights:

(1) Wall tiles have cross seams (e.g. V-stitches, grooves), the use of graphic 1 practice, the end should be 45 degrees stitching diagonal treatment (angle slightly less than 45 degrees, to facilitate stitching), cut should be processed in the factory (glazed brick can be processed on-site);, you can use the illustration of the yin 2 approach.

(2) Wall brick anode closings should be 45 degrees stitching diagonal treatment (angle slightly less than 45 degrees, to facilitate stitching), anode incision.

(3) It should be finished in the factory (glazed bricks can be processed on-site). Yangjiao closing when spelling should be 1mmaway from the seam, with a filler to fill the seam, to prevent the edge, cracking. See illustration of Yangyang 1 practice.

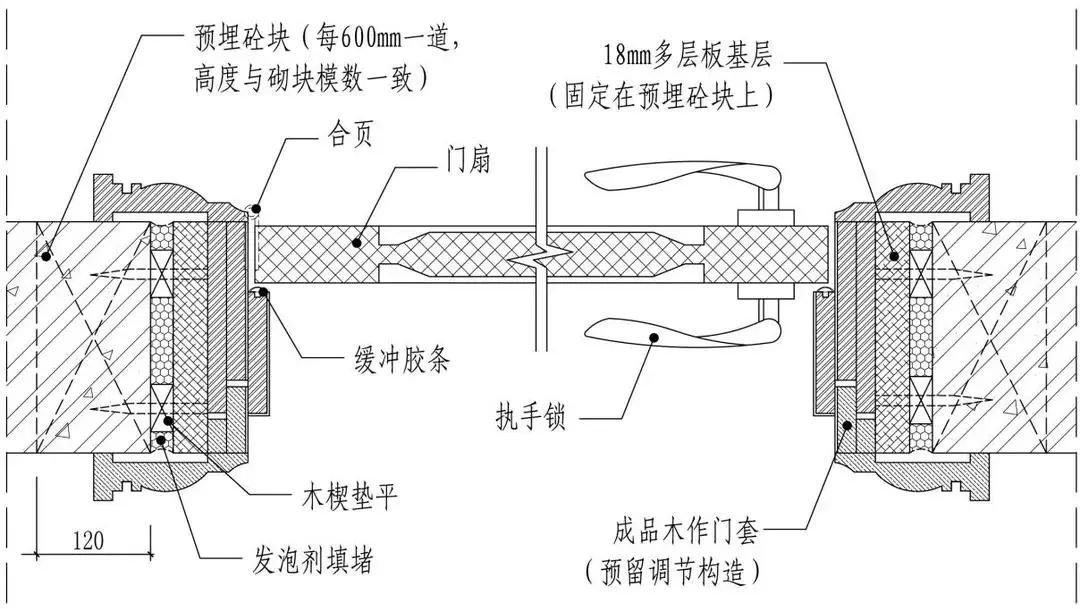

The finished door cover construction schematic:

Highlights:

(1) When building a door hole, the vertical direction on both sides of the door hole should not be less than 150mmup and down, the middle is not less than 500mm,pre-buried a 120mm wide block, the door frame base should be fixed on the block.

(2) The door frame base uses an 18mm multi-layer board and makes three anti-treatment.

(3) The space between the wood baseboard and the side of the door cover should be filled with a foaming agent.

Bathroom door fan bottom off the threshold stone finish surface 8to12mm, room door fan bottom threshold stone finish surface 5to8mm. Doors need to be equipped with door suction or door resistance, installation location is determined according to the actual location of the site.

4.2

Craft model

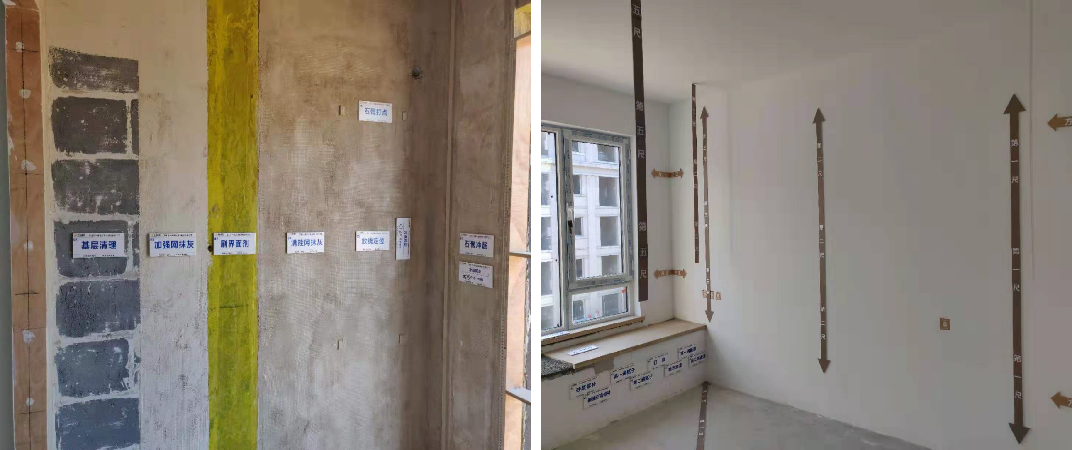

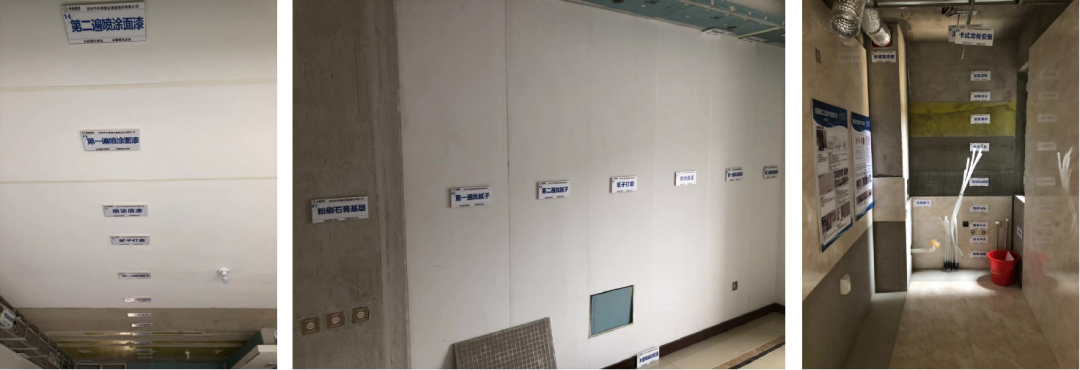

Paint the gypsum process / measured amount

Smallpox keel process / window sill stone process / window sill stone closing process

Ceiling latex lacquer process / wall latex paint process / wall brick process

Ground leveling process / floor tile process / wood flooring process

Between solid models

05

Close pin item

5.1

Close pin item

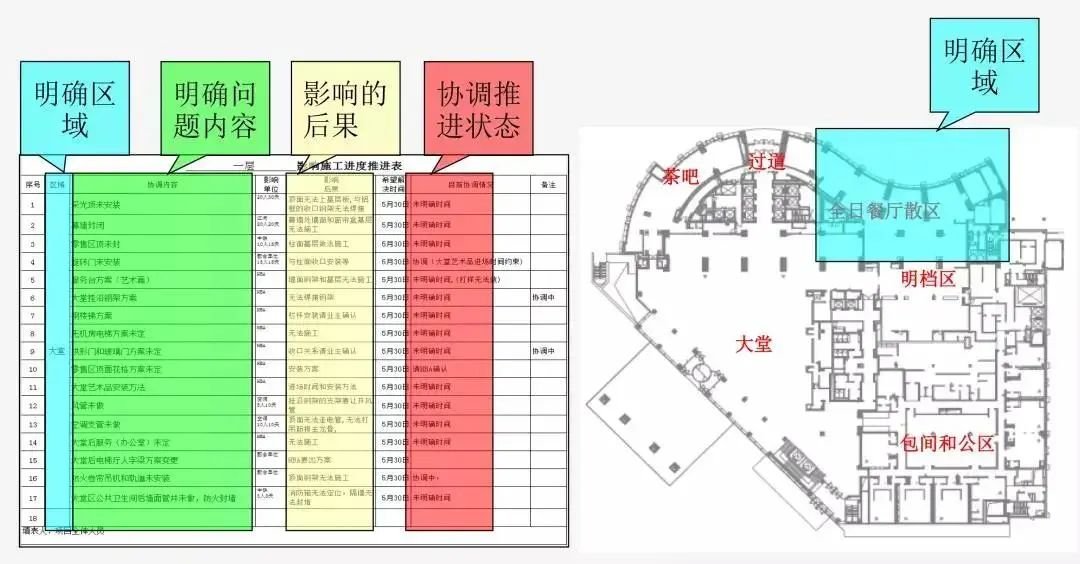

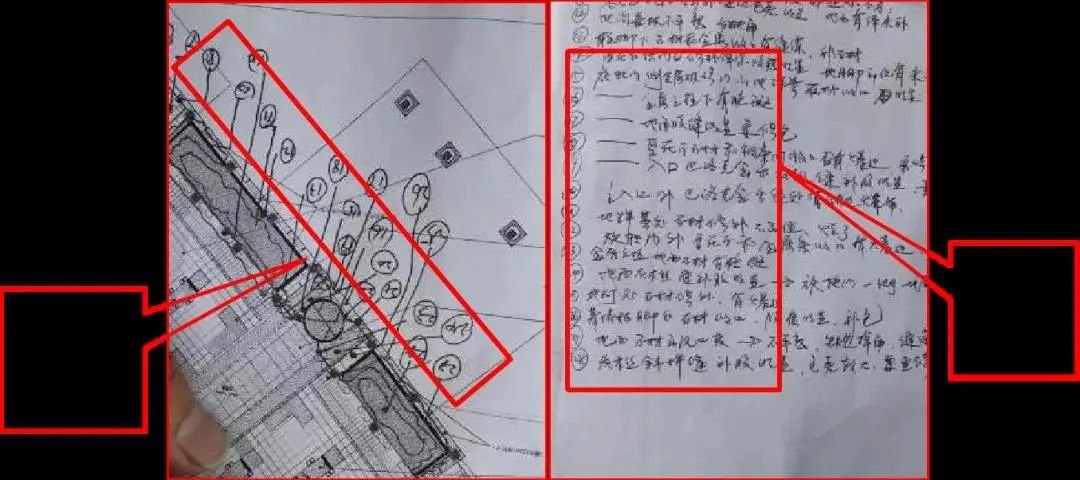

Quantify on the drawings, specific to each floor, every area, every room:

Impact on the construction schedule

Affects the relationship between the construction schedule and the regions

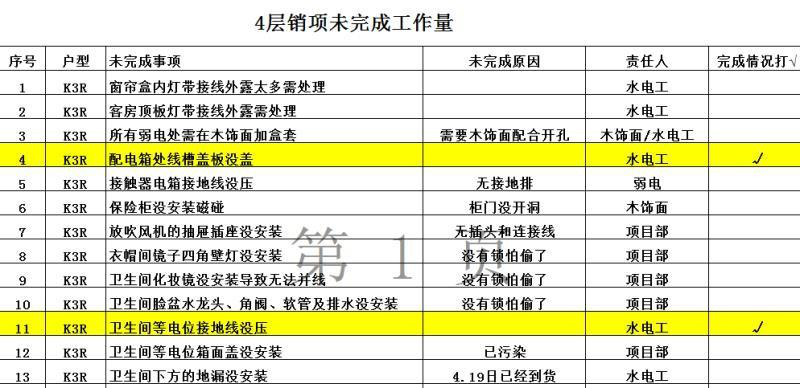

According to the summary list of problems, the preparation of mechanical and electrical special elimination form, arrange for a person to check the completion of the situation every day, and report the results to the highest leadership on the scene of Party A:

On-site mechanical and electrical is not completed into the engineering list

To organize the key difficult issues of mechanical and electrical impact decoration progress, the project manager is responsible for the promotion, item by item:

Impact construction schedule – Electromechanical items

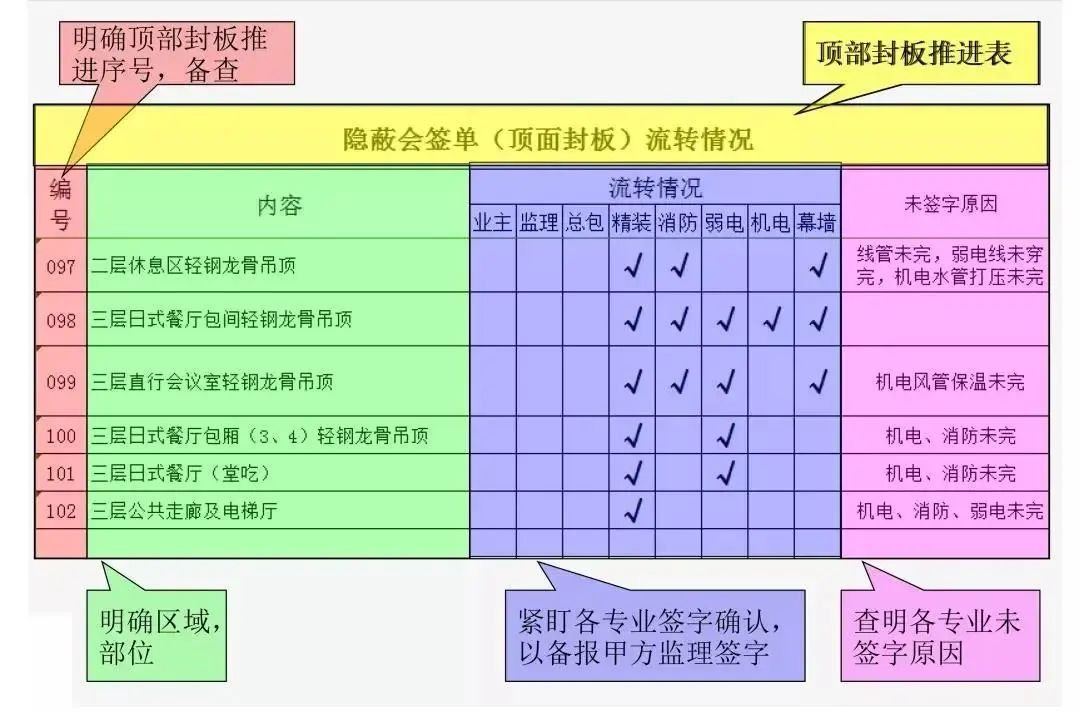

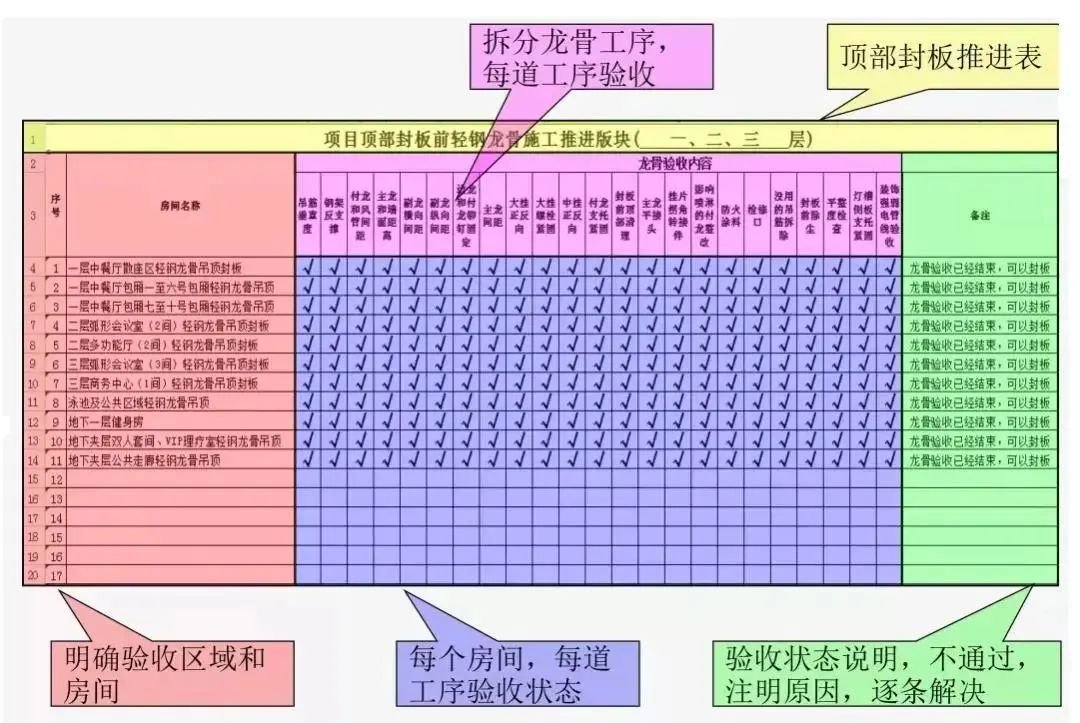

Before sealing the board, focus on the progress of mechanical and electrical construction, the preparation of special forms dedicated to checking the actual progress of the site every day, and the electronic version reported to Party A site top leadership:

The flow of the concealed check-back order (top seal plate).

Before the construction of the sealing board, improve the keel preparation within the scope of their contract, and prepare special forms, daily implementation of progress, according to the requirements of the overall schedule plan, to carry out purposeful progress management.

The flow of the concealed check-back order (top seal plate).

06

Centralized delivery

6.1

Forced finishing

To organize a list of refined problems (list of sales items): Work with the project engineering department to sort out all the problems to be transferred to the area, compile a list of problems, by Party A, for the particularity of the project, special clarification, the maintenance responsibility party clear.

Quantify on the drawings, specific to each floor, every area, every room: put the quality problems existing on the site into the drawings, and form a written record, with physical photos. The project manager organizes point-to-point repairs.

The person is responsible for the promotion of the sales item: every day and Party A, the total package for pre-acceptance of the sales item signature confirmation.

Finishing the key difficulties of finishing, the project manager is responsible for promoting, item by item: for the key difficulties in the content of the maintenance pin items, the project manager fixed-point tracking, the implementation of human and material resources, fixed-point solution.

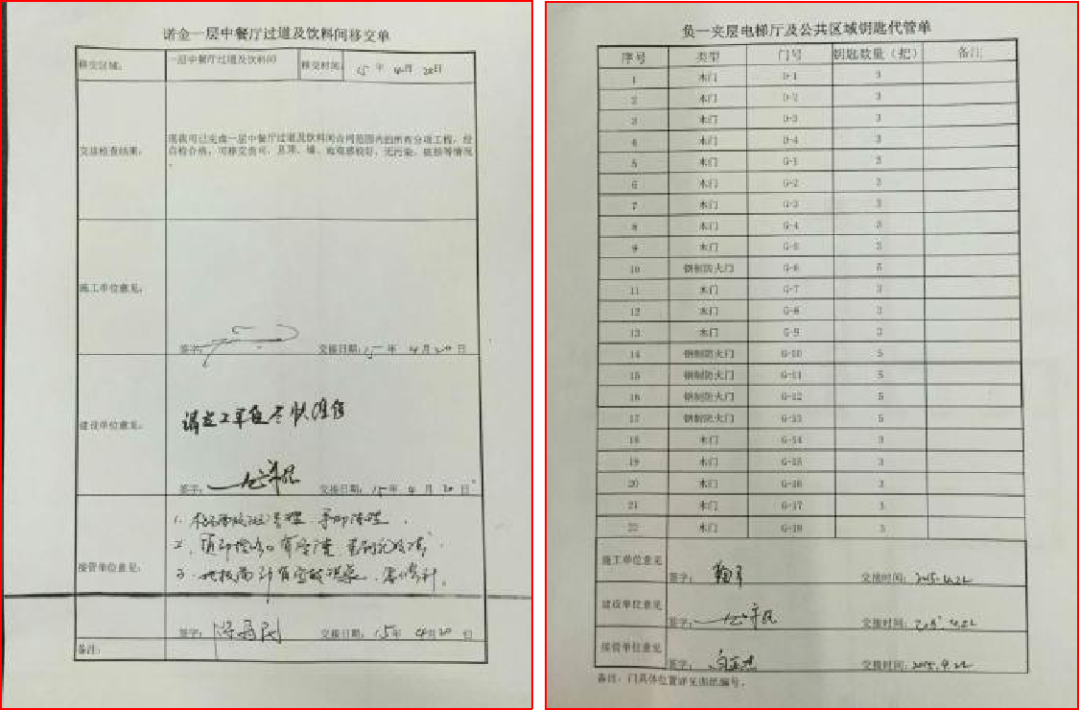

Overall acceptance transfer: When the maintenance contents in the repair item list form are eliminated, the project department organizes Party A, supervision, hotel management, and use of the site transfer, sub-floors or areas, for complete acceptance and acceptance of the qualified transfer.

6.2

Household inspection

Time node:

Note:

Renovation company self-inspection:

(1) by the decoration company project manager organization, technical person in charge, and quality inspector-led acceptance team;

(2) Prepare A3 floor plan paper for acceptance issue labeling;

(3) At the same time fill in the acceptance question summary form for sales maintenance;

(4) Prepare eye-catching stickers, box ruler, caliper, 2-meter ruler, rangefinder, stopper, infrared level. Empty drums, digital cameras, and other full set of acceptance tools;

(5) Acceptance of four – eight sets per day;

(6) Elimination repairs are carried out on the second day of acceptance,5-7 days before the repair is completed the day before the problem.

Quartet Joint Acceptance:

(1) by the real estate hardcover group, property engineering department, supervision company, decoration company composition;

(2) First check the decoration company’s general statement of acceptance of sales items;

(3) According to the decoration company acceptance method for acceptance (drawing labeling method, wall paste eye-catching instant paste, acceptance of the general table).

(4) Acceptance includes test drive (overall commissioning of mechanical and electrical systems).

Owner pre-acceptance:

(1) A notice is issued by marketing to the owner;

(2) Determine the owner’s pre-acceptance date;

(3) Form the owner acceptance form and sign;

(4) Issue a repair order, pin repair

(5) Deep cleaning (including crystallization).

Completion acceptance before delivery:

(1) The last joint acceptance of the Quartet;

(2) Local rectification;

(3) handover with the property;

(4) Marketing notice to the owner to accept the house;

(5) Rectification, maintenance;

(6) The Engineering Department will escort for 3 months.